For a printable version of newsletter click here.

For a printable version of newsletter with photos click here.

For a printable version of newsletter with photos click here.

Merry Yuletide! wishes you your Einkorn. And Grünkern.

It’s December, and not much to report about the Einkorn field on the Columbia Plateau. The winter grass bears the cold through abstinence of growth, waiting. When snow layers accumulate, the grass flattens. Waiting. Lasting. Cold-season endurance.

Under weakening sun, through spewing storm, inside sprawling fog, the deer herds survive cautiously, and the little rabbits. Coyote stalks. Although, there is more wildlife activity than meets the eye, the evidence of this the multitude of tracks in new snow along the wildlife strip of grain left standing at the Lentz Farm. A lot of scurrying rodents amid the wizened stalks.

One wintry afternoon an owl visits, perching close to the kitchen window in the lilac bush. It’s the Christmas Owl.

It’s December, and not much to report about the Einkorn field on the Columbia Plateau. The winter grass bears the cold through abstinence of growth, waiting. When snow layers accumulate, the grass flattens. Waiting. Lasting. Cold-season endurance.

Under weakening sun, through spewing storm, inside sprawling fog, the deer herds survive cautiously, and the little rabbits. Coyote stalks. Although, there is more wildlife activity than meets the eye, the evidence of this the multitude of tracks in new snow along the wildlife strip of grain left standing at the Lentz Farm. A lot of scurrying rodents amid the wizened stalks.

One wintry afternoon an owl visits, perching close to the kitchen window in the lilac bush. It’s the Christmas Owl.

Let’s talk of Angels. Angels of straw.

This is their history:

When we humans lived in nature, each living kind on earth was imbued with spirit. This spirit, this essence was experienced, the essence of bear, the essence of the Tannenbaum, even the essence of crystal stone and the essence of rock formations.

Thus is animism, the spirituality that preceded religions. We all have this nimbus in our deep background. Since animism still survives in a few tribal societies it can be studied, in its diversity and its similarities.

One of the similarities is totem, idol, fetish, cave painting. A representation, that is, of a spirit held in awe, an essence worshipped; more: a representation as an appeasement, or of thanks-giving – in many American Indian tribes, for example, the hunter would offer a prayer of thanks to the spirit of the deer he’d killed for food.

And how would you thank Einkorn?, in those very early days when nomads domesticated its non-shattering traits, how would you represent your hope for the newly-sown Einkorn stand to grow and ripen?

You would make a figure of Einkorn straw, starting a custom that would endure until tomorrow. You made a straw fetish when you still wandered and gathered, you made a straw idol after you’d settled as agrarian, you made straw idols under paganism, and you still make straw idols, as German industrial farmer, for instance. Of course, most of today’s straw weavings are no longer “idols” but European Christian imagery. To wit, the shining straw angel atop the Christmas tree.

Yes, angels exist.

This is their history:

When we humans lived in nature, each living kind on earth was imbued with spirit. This spirit, this essence was experienced, the essence of bear, the essence of the Tannenbaum, even the essence of crystal stone and the essence of rock formations.

Thus is animism, the spirituality that preceded religions. We all have this nimbus in our deep background. Since animism still survives in a few tribal societies it can be studied, in its diversity and its similarities.

One of the similarities is totem, idol, fetish, cave painting. A representation, that is, of a spirit held in awe, an essence worshipped; more: a representation as an appeasement, or of thanks-giving – in many American Indian tribes, for example, the hunter would offer a prayer of thanks to the spirit of the deer he’d killed for food.

And how would you thank Einkorn?, in those very early days when nomads domesticated its non-shattering traits, how would you represent your hope for the newly-sown Einkorn stand to grow and ripen?

You would make a figure of Einkorn straw, starting a custom that would endure until tomorrow. You made a straw fetish when you still wandered and gathered, you made a straw idol after you’d settled as agrarian, you made straw idols under paganism, and you still make straw idols, as German industrial farmer, for instance. Of course, most of today’s straw weavings are no longer “idols” but European Christian imagery. To wit, the shining straw angel atop the Christmas tree.

Yes, angels exist.

*****

In pagan Europe, “the Corn Mother was a spirit that could be protected in woven grain symbols," we’re told by wheat weaver Phyllis Franz of Moses Lake, Washington. (The English “corn” doesn’t mean maize but “cereal grain.”) Franz explained that Corn Dollies is the term for the ancient wheat fetishes – “the word 'Dolly' (doll) is likely derived from 'idol.’

"Corn Dollies were accepted into churches as part of their harvest thanksgiving festivals. Many were in the shape of crosses."

When threshing machines appeared and life styles turned away from handicraft, the art of wheat weaving almost died out. A key event in the resurrection of straw art were woven wheat displays at the 1951 Festival of Britain, Franz said. "The craft was revived without the religious aspects. Today England is the Mecca of wheat weaving."

The uplift of American straw art she ascribes to 1974 when Mennonites in Kansas celebrated the centennial of the immigration of Germans from Russia who brought Turkey Red wheat to the Midwest. In honor of the Turkey Red that contributed greatly to the bread basket role Kansas had come to play, members of the Bethel College Women's Association wove Turkey Red wheat mementos.

The following year, Franz related, her wheat weaving friend Adelia Stucky came out from Kansas for a visit. "It was harvest when she came. I was cooking for 13 men."

Franz ran between the kitchen and the garage where her friend was teaching wheat weaving to the wives of the harvest crew.

Ever since, Franz has woven straw. "It's like knitting," she said. "I do it at home, I do it riding in the car, I do it when (her husband) Victor is fishing."

In 1987 the (American) National Association of Wheat Weavers was founded; in 2003 their annual convention drew about 100 straw artists to Spokane, Washington. Morgyn Geoffry Owens-Celli, director and curator of the American Museum of Straw Art in Long Beach, California taught one of the classes. It featured the Peace Bird, based on the folk art of Larisa Los, of Minsk, Belarus whom he called "the Grandmother of Straw." Two hours of finger-twisting about 300 pieces of straw created a proud bird standing, while Owens-Celli shared stories of his globe trotting on behalf of straw culture.

Speaking of the straw art museum, Owens-Celli noted that their collection represents 57 cultures, each with its own wheat weaving styles. "England, for instance, is just a small, little country, yet the designs in Devon are totally different from those in Suffolk." The best known American cultural pieces, he said, are the Pennsylvania hex symbols of straw.

The short straw of industrial wheats doesn’t do much for straw art, so a little trade has developed specializing in wheat weaving straw. At the convention, weaving-wheat sellers offered a wide variety of straw typically raised in plots. A large box of "fine weaving-wheat" can fetch as much as $250. The old Turkey Red is still represented; particularly popular are black-bearded durum cultivars; other favorites are varieties of Spelz which is the long-bearded Emmer of North Dakota.

"Corn Dollies were accepted into churches as part of their harvest thanksgiving festivals. Many were in the shape of crosses."

When threshing machines appeared and life styles turned away from handicraft, the art of wheat weaving almost died out. A key event in the resurrection of straw art were woven wheat displays at the 1951 Festival of Britain, Franz said. "The craft was revived without the religious aspects. Today England is the Mecca of wheat weaving."

The uplift of American straw art she ascribes to 1974 when Mennonites in Kansas celebrated the centennial of the immigration of Germans from Russia who brought Turkey Red wheat to the Midwest. In honor of the Turkey Red that contributed greatly to the bread basket role Kansas had come to play, members of the Bethel College Women's Association wove Turkey Red wheat mementos.

The following year, Franz related, her wheat weaving friend Adelia Stucky came out from Kansas for a visit. "It was harvest when she came. I was cooking for 13 men."

Franz ran between the kitchen and the garage where her friend was teaching wheat weaving to the wives of the harvest crew.

Ever since, Franz has woven straw. "It's like knitting," she said. "I do it at home, I do it riding in the car, I do it when (her husband) Victor is fishing."

In 1987 the (American) National Association of Wheat Weavers was founded; in 2003 their annual convention drew about 100 straw artists to Spokane, Washington. Morgyn Geoffry Owens-Celli, director and curator of the American Museum of Straw Art in Long Beach, California taught one of the classes. It featured the Peace Bird, based on the folk art of Larisa Los, of Minsk, Belarus whom he called "the Grandmother of Straw." Two hours of finger-twisting about 300 pieces of straw created a proud bird standing, while Owens-Celli shared stories of his globe trotting on behalf of straw culture.

Speaking of the straw art museum, Owens-Celli noted that their collection represents 57 cultures, each with its own wheat weaving styles. "England, for instance, is just a small, little country, yet the designs in Devon are totally different from those in Suffolk." The best known American cultural pieces, he said, are the Pennsylvania hex symbols of straw.

The short straw of industrial wheats doesn’t do much for straw art, so a little trade has developed specializing in wheat weaving straw. At the convention, weaving-wheat sellers offered a wide variety of straw typically raised in plots. A large box of "fine weaving-wheat" can fetch as much as $250. The old Turkey Red is still represented; particularly popular are black-bearded durum cultivars; other favorites are varieties of Spelz which is the long-bearded Emmer of North Dakota.

*****

Straw alive: we travel to Fürth, a Franconian city famous for its Erntedankfestzug – its Harvest-Thanksgiving Parade.

Keep in mind that Europe’s Thanksgivings are not about Pilgrims and Indians; here the festival is a genuine giving thanks for local crops reaped. The timing of Erntedankfests varies, most communities celebrate their thanksgiving on a weekend in October.

At Fürth some 80,000 onlookers lined the parade route (according to the next day’s newspaper). Hundreds of balloons bolted for the sky as starting signal to the over 60 parade entries – floats pulled by majestic draft horses all decked out, or pulled by oxen, or by tractors. Marching bands galore filled the street with brass sound and drum roll, the musicians in a grand variety of traditional costumes. A contingent of butchers strutted by, followed by house painters, behind them marched carpenters. And clubs paraded: it was as though every Dorf in the region had sent their football club, music club, shooting club to step lively and wave to the crowds. As a German matter of course, several breweries featured barrel-laden festive trailers.

Keep in mind that Europe’s Thanksgivings are not about Pilgrims and Indians; here the festival is a genuine giving thanks for local crops reaped. The timing of Erntedankfests varies, most communities celebrate their thanksgiving on a weekend in October.

At Fürth some 80,000 onlookers lined the parade route (according to the next day’s newspaper). Hundreds of balloons bolted for the sky as starting signal to the over 60 parade entries – floats pulled by majestic draft horses all decked out, or pulled by oxen, or by tractors. Marching bands galore filled the street with brass sound and drum roll, the musicians in a grand variety of traditional costumes. A contingent of butchers strutted by, followed by house painters, behind them marched carpenters. And clubs paraded: it was as though every Dorf in the region had sent their football club, music club, shooting club to step lively and wave to the crowds. As a German matter of course, several breweries featured barrel-laden festive trailers.

Agricultural floats were prominent, especially those representing Knoblauchland, the famous “Garlic Country” region north of Fürth. Some floats bearing a Thanksgiving Crown carried amassed vegetables tightly packed in colorful pattern, one was a tall crown of radishes, another of mini-pumpkins rising above veggie pyramids.

At central place in the parade floated the traditional Crown of Cereal, its upward curving struts of straw and bound grain heads conveying simple grace. Ten feet tall, the laboriously constructed straw art stood apart from the vegetable crowns – if those seemed to be in a frolic, the Cereal Crown imparted gravitas, the solemnity of the Daily Bread. By the straw length it was obvious that Spelt and Emmer are again raised in this region.

After the parade the crowds streamed to the Kärwa – Franconian for Kirchweih, elsewhere also called Kirmes or Kilbi, an annual fair in commemoration of the consecration of the local church. At Fürth it’s a large Kärwa, clusters of carnival rides beside a mile-long passage of food booths selling pretzels and sausages, cheeses, chocolate, fried spuds and Spätzle noodles and fish, among beer huts, so many festal beer huts. Clearly it was time to feast.

Cereal Crowns at Thanksgiving and Kärwa are not the only straw custom of large size to survive into our time. Most imaginative is perhaps the Straw Bear when he roars and rolls about the villages, in Bohemia and Poland, Switzerland, England. In Plaue, Thuringia the Straw Bear belongs to Kirmes, says Jürgen Grau. “In Plaue Kirmes is held in the fall, after harvest when the field work has wound up. On Saturday they put on a big dance, and on Sunday there is a procession of guys, the Kirmesburschen. The volunteer firemen are usually part of the troupe. They go from house to house dressed up in funny costumes. One year they went around as Vikings, I remember. They call out to the people in the houses, and toast the family. They carry tin boxes, for coins. The big Straw Bear is always part of that procession.”

As a little boy, was he scared of the Straw Bear? “No, no,” Grau says. “The Straw Bear is not scary, he’s a funny figure. He’s a kind of mascot.”

In other regions the Straw Bear customs belong to Shrovetide, the Fat Tuesday of Mardi Gras. In some traditions, to touch the dancing straw bear transfers fertility to young women; still other customs include the burning of the straw shape (after the dancer has slipped out of the straw, of course) at the end of the festivities.

The bright combustibility of straw also figures in the custom of the Feuerrad, the fire wheel. A man-sized wheel is built and stuffed with straw atop a hill; set afire, the flaming circle representing the sun is then sent downhill in a spectacular celebration of either Solstice, Shrovetide, or Easter. This tradition is still alive in the regions of the Neckar and Mosel rivers. Jakob Grimm, one of the Brothers Grimm, found mysticism in the Feuerrad: “...it looks as though the sun is racing down from the sky.”

After the parade the crowds streamed to the Kärwa – Franconian for Kirchweih, elsewhere also called Kirmes or Kilbi, an annual fair in commemoration of the consecration of the local church. At Fürth it’s a large Kärwa, clusters of carnival rides beside a mile-long passage of food booths selling pretzels and sausages, cheeses, chocolate, fried spuds and Spätzle noodles and fish, among beer huts, so many festal beer huts. Clearly it was time to feast.

Cereal Crowns at Thanksgiving and Kärwa are not the only straw custom of large size to survive into our time. Most imaginative is perhaps the Straw Bear when he roars and rolls about the villages, in Bohemia and Poland, Switzerland, England. In Plaue, Thuringia the Straw Bear belongs to Kirmes, says Jürgen Grau. “In Plaue Kirmes is held in the fall, after harvest when the field work has wound up. On Saturday they put on a big dance, and on Sunday there is a procession of guys, the Kirmesburschen. The volunteer firemen are usually part of the troupe. They go from house to house dressed up in funny costumes. One year they went around as Vikings, I remember. They call out to the people in the houses, and toast the family. They carry tin boxes, for coins. The big Straw Bear is always part of that procession.”

As a little boy, was he scared of the Straw Bear? “No, no,” Grau says. “The Straw Bear is not scary, he’s a funny figure. He’s a kind of mascot.”

In other regions the Straw Bear customs belong to Shrovetide, the Fat Tuesday of Mardi Gras. In some traditions, to touch the dancing straw bear transfers fertility to young women; still other customs include the burning of the straw shape (after the dancer has slipped out of the straw, of course) at the end of the festivities.

The bright combustibility of straw also figures in the custom of the Feuerrad, the fire wheel. A man-sized wheel is built and stuffed with straw atop a hill; set afire, the flaming circle representing the sun is then sent downhill in a spectacular celebration of either Solstice, Shrovetide, or Easter. This tradition is still alive in the regions of the Neckar and Mosel rivers. Jakob Grimm, one of the Brothers Grimm, found mysticism in the Feuerrad: “...it looks as though the sun is racing down from the sky.”

The boisterous Feuerrad celebration does not end of our straw imagery discussion. A modern esoteric dimension also exists: take the elevator up a high-rise, then step into a hallway of office doors echoing high-heel business fashion, look up and note the floral art tastefully displayed on white wall, floral art starring among dried flowers prominent wheat sheaves.

Some of those sheaves come from Latah, Washington where Gary Schafer grows several tracts of durum wheats and oats for floral wholesale as a retirement enterprise. In late July we find Schafer bent over a strange contraption resembling a rototiller. Kubota is the manufacturer of the machine: "It's a rice binder from Japan," Schafer explained.

Two shiny tines are positioned up front to gather two rows of grain stalks that are then cut by a small sickle bar and wrapped with twine. A small knotter finishes each bundle that then flops sideways out of the machine.

The thermometer reads 97 degrees Fahrenheit but the field needs to be cut, sweat and dust notwithstanding. "Everything in this business is about quality," Schafer noted. "If your stuff isn't quality, forget it." And floral straw quality means that wheat and oats have to be cut at precisely the right growing stages, in two harvests, one right before the stalks turn color, and one before the kernels harden. "One more day and these oats will start turning color. We're cutting just in time,” Schafer said. The rice binder harvests about 1/8 acre of straw in an hour.

The straw bundles end up by a tin-roof shed. It's dark inside, like in an oven, perfect for bundle drying but breath-taking – the hot air is thick when you're hanging the bundles. One by one the bundles get handled, carefully, and any wild oats – identifiable by their slightly taller growth – are pulled out.

In another shed Schafer checks on the durum wheat bundles that were hung up the day before. "When the bundles are dry they've lost about 65 percent of their field weight," he said.

Much of floral wheat business today consists of retail sales to hobbyists, and the prices are dear, as high as $5.90 per 8 ounces, $12 for bundled wheat and oat sheaves 24 inches long.

But Schafer doesn’t mess with retail. "I get paid by the pound, they (his floral company customer) sell by the ounce.”

The commercialization of dried floral art originated when the zeitgeist favored natural materials again after the plastic-flower craze of the 1950s and 1960s. By the 1980s dried flowers were so much in demand that Washington's Okanogan County experienced quite the boom in baby's breath production, a gypsophila weed growing wild there since the 1930s.

On market trends Schafer remarked that dried floral art is still growing in popularity. "Quite a bit of oats and wheat are used in the kind of wreaths you see in office buildings.”

Some of those sheaves come from Latah, Washington where Gary Schafer grows several tracts of durum wheats and oats for floral wholesale as a retirement enterprise. In late July we find Schafer bent over a strange contraption resembling a rototiller. Kubota is the manufacturer of the machine: "It's a rice binder from Japan," Schafer explained.

Two shiny tines are positioned up front to gather two rows of grain stalks that are then cut by a small sickle bar and wrapped with twine. A small knotter finishes each bundle that then flops sideways out of the machine.

The thermometer reads 97 degrees Fahrenheit but the field needs to be cut, sweat and dust notwithstanding. "Everything in this business is about quality," Schafer noted. "If your stuff isn't quality, forget it." And floral straw quality means that wheat and oats have to be cut at precisely the right growing stages, in two harvests, one right before the stalks turn color, and one before the kernels harden. "One more day and these oats will start turning color. We're cutting just in time,” Schafer said. The rice binder harvests about 1/8 acre of straw in an hour.

The straw bundles end up by a tin-roof shed. It's dark inside, like in an oven, perfect for bundle drying but breath-taking – the hot air is thick when you're hanging the bundles. One by one the bundles get handled, carefully, and any wild oats – identifiable by their slightly taller growth – are pulled out.

In another shed Schafer checks on the durum wheat bundles that were hung up the day before. "When the bundles are dry they've lost about 65 percent of their field weight," he said.

Much of floral wheat business today consists of retail sales to hobbyists, and the prices are dear, as high as $5.90 per 8 ounces, $12 for bundled wheat and oat sheaves 24 inches long.

But Schafer doesn’t mess with retail. "I get paid by the pound, they (his floral company customer) sell by the ounce.”

The commercialization of dried floral art originated when the zeitgeist favored natural materials again after the plastic-flower craze of the 1950s and 1960s. By the 1980s dried flowers were so much in demand that Washington's Okanogan County experienced quite the boom in baby's breath production, a gypsophila weed growing wild there since the 1930s.

On market trends Schafer remarked that dried floral art is still growing in popularity. "Quite a bit of oats and wheat are used in the kind of wreaths you see in office buildings.”

*****

Since we’re on the topic of straw, how about the multitude of utilitarian facets of straw? Of course, of course you’re thinking of the drinking straw but be careful here – if you remember when straws were actually wheat straw you’re dating yourself.

The drinking straw actually figures prominently in dawn-of-agriculture scenarios, so informs us Michael Pollan in his latest writing, Cooked, © 2013. The first beers existed beneath floating crud caused by primitive fermentation methods; the Sumerians for one used straws to get through the crud at the beer. Since the high of alcohol consumption is central to virtually every early and not so early religion, the straw for the ritual is worth contemplating, in our book.

Arguing that cereal use for beer preceded bread and porridge – a speculation similar to the one they’re discussing at the Deutsches Archäologisches Institut in Berlin –, Pollan goes so far as to explain agricultural beginnings in terms of beer. Did civilization arise because people wanted to have fermentation-friendly materials on hand year-round, rather than search for them in nature where they aren’t all that readily found?, he asks.

But back to straw. Dry grass in general served a number of functions over the millennia. On the African plains the construction of grass straw huts began at least as early as the paleolithic.

Cereal straw is a special type of dry grass, distinguished by several traits including the hollow characteristic and internode length. Historically it’s likely that straw traits such as straw strength were considered when farmers selected from newly occurring cereal genotypes.

In traditional farming systems straw features to this day.

The drinking straw actually figures prominently in dawn-of-agriculture scenarios, so informs us Michael Pollan in his latest writing, Cooked, © 2013. The first beers existed beneath floating crud caused by primitive fermentation methods; the Sumerians for one used straws to get through the crud at the beer. Since the high of alcohol consumption is central to virtually every early and not so early religion, the straw for the ritual is worth contemplating, in our book.

Arguing that cereal use for beer preceded bread and porridge – a speculation similar to the one they’re discussing at the Deutsches Archäologisches Institut in Berlin –, Pollan goes so far as to explain agricultural beginnings in terms of beer. Did civilization arise because people wanted to have fermentation-friendly materials on hand year-round, rather than search for them in nature where they aren’t all that readily found?, he asks.

But back to straw. Dry grass in general served a number of functions over the millennia. On the African plains the construction of grass straw huts began at least as early as the paleolithic.

Cereal straw is a special type of dry grass, distinguished by several traits including the hollow characteristic and internode length. Historically it’s likely that straw traits such as straw strength were considered when farmers selected from newly occurring cereal genotypes.

In traditional farming systems straw features to this day.

Maize stalks in Romania:

Barley straw in Bolivia (photos courtesy of Steve Caudill):

There’s thatch, in Scotland for example:

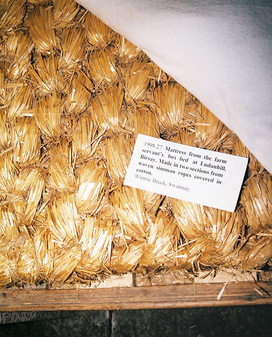

Woven straw mattresses, also Scotland:

Straw hats in the Americas:

Straw baskets. Paper made from Spelt straw at Lentz Farms:

Ah, and one more straw use, what might seem an outlandish one (yep, in France): cheese makers use rye straw as bed for their ripening cheese, because rye developed a symbiosis with Trichothecium roseum, “the flower of molds,” so Pollan tells us.

*****

After millennia of straw blessings of every conceivable aspect, we arrive at the straw of industrial farming. And what do we encounter but a huge straw problem with its accompanying political controversy.

On the surface everything seems alright: a major use for Washington wheat straw is as bedding for livestock, especially dairy cows. Less known but also important is straw for the mushroom industry west of the Cascades, wheat straw the main ingredient of the medium in which the fungi are raised.

Another straw use is by the Forest Service. In the autumn after a forest fire, big straw bales are trucked to a nearby landing. From there the bales are lifted in a net by helicopter and flown to hillsides made vulnerable by the burn. The catch of the net is released and the straw drops toward the steep ground, spreading as it flies. The point of this expensive operation is to reduce erosion. To avoid weed seed spread, the Forest Service sources straw from seed wheat fields that have been certified as weed-free.

So where is the straw problem? The above cited byproduct markets absorb only a small fraction of the straw that needs to be removed from the fields.

Why doesn’t straw stay on the fields? It does, on low-rainfall dryland (dryland receiving less than 12 inches of annual precipitation) all straw is left in the field as a soil building measure. However, on high rainfall dryland and on irrigated acreage the industrial wheats produce too much straw residue, a straw mass so large that it doesn’t break down properly.

Stephen Machado of Oregon State University explained to us that when you grow wheat on wheat, stubble and straw add up to a carbon-nitrogen ratio so high that much of the nitrogen is unavailable to the wheat. In fact, "wheat may become auto-toxic (toxic to itself) in monoculture systems.” This is especially the case in the chemical no-till system that the government currently promotes.

The auto-toxic effect of wheat straw has been known for some time; farmers conventionally resorted to field burning when wheat straw baling was not an option. Back then it was also felt that occasional field burning kept in check some plant diseases and pests.

But in the 1990s the government outlawed most field burning, citing air quality problems caused by the fires.

Whenever government tries to regulate agriculture you get – you guessed it – controversy. Commodity market margins are often so tight that every single field operation needs to pencil out. And now, with field burning restrictions, the government was in effect demanding mechanical straw removal without ready renumeration for the grower.

Across the Pacific Northwest, the field burning controversy resulted in much probing for alternative straw uses.

You’ve heard of straw bale houses? They go back to the first horse-drawn balers of the mid-1800s, said Michael Thomas who together with his wife, Spring Thomas, founded the non-profit IronStraw Group in Ellensburg, Washington. "In Nebraska they invented methods of building with straw bales in areas where the ground was sandy, where there was no sod for building," Thomas elaborated. "Old straw buildings exist in other states, too; a famous one is the Burritt Museum in Huntsville, Alabama that was built as a private home with straw bales in 1938."

The 1970s saw a revival of straw bale construction in the context of the back-to-the-land movement.

As licensed building contractor, Thomas combined straw bale building practicality with 21st-century concepts such as "eco-building," "straw-bale neighborhoods," "nature-based construction." Most famously, he straw-bale-built the Mattawa, Washington public library in 2002.

If Thomas as environmentalist developed good relationships with farmers, those farmers also pointed out soon enough that straw bale building is not likely to amount to much of a straw market, not in the big picture: that Mattawa library, for instance, measures 1500 square feet and required only 310 straw bales. To put that number into a per-acre perspective, consider that three-string straw bale production on an irrigated Spelt field averages over 50 bales to the acre.

Enter David Ward, of Ashland, Oregon. He invented the Strawjet that earned the 2006 Modern Marvel of the Year Award. According to a press release, the panel of experts who judged the submissions from 4300 inventors declared the Strawjet the winner because of its “potential to make a dramatic global impact..."

It certainly is innovative. Ward told us that his Strawjet is a combine-harvester attachment that twists the straw into 2-inch diameter cables, on the go. "They're tightly bundled cables, they're like a round straw bale 2 inches thick. The machine lays down four cables with each pass. The way the hardware is designed, it can also be used as a stand-alone, mounted on a pick-up or tractor," Ward said.

The straw cables stretching across the field are picked up by a "loom machine," he explained. "The loom machine is basically a stack-wagon with a looming mechanism that cuts and weaves the straw cable so it looks like a giant bamboo window blind, each 8 feet long and 5 feet in diameter."

The next step in the process is to infuse the straw weave with a clay-based or cement-based binder. Ward compared the straw weave to the cloth in fiberglass. "It's like making a fiberglass boat, with the mats rolled out."

The final product in the field are building panels 8 feet tall and 14 feet to 16 feet long. These panels are to be loaded by a crane for transport. "Construction with the panels is a lot like construction with cement panels."

Ward envisioned countless uses for Strawjet-generated building materials, especially in Third World countries.

But Chad Kruger, specialist in carbon management issues as director of the Climate-Friendly Farming Project at Washington State University, was skeptical. "In the past there have been myriads of technologies to help poor countries,” Kruger said. “What happens a lot of times is that once the (funded) project goes away, the technology disappears – the real issue is the adoption of technology. One example are the kerosene refrigerators, Third World people just didn't take to that technology."

Closer by, in 2002, hopes for extensive straw use were raised when Ponderosa Fiber was poised to re-open for business as a pilot mill within the large Boise Cascade facility at Wallula, Washington. Bill Snyder, part owner and president of Universal Pulping in Eugene, Oregon was one of the players trying to get the Ponderosa Fiber straw pilot off the ground.

Universal Pulping was founded in 1994, its purpose to “commercialize a novel pulping process called Universal Pulping that uses extremely diluted chemicals,” Snyder said. The new process was initially developed in Europe in the mid-1970s; the patent was awarded to Eric Prior, of West Germany, in 1987.

Universal Pulping differs from conventional paper manufacture – called the Kraft Process – in how the raw fiber is broken down, Snyder elaborated. Whereas the Kraft process requires a “digester” that operates with 100-pound-per-square-inch pressure at temperatures of several hundred degrees Celsius, Universal Pulping requires no pressurizing and creates less heat than boiling.

By implementing the universal pulping technology, Snyder noted, “we believe that the economics work out to where Ponderosa Fiber can operate profitably even in a depressed (pulp) market, at a time when the American paper industry has more capacity than demand. We feel it’s a unique opportunity.” Straw use would be considerable: “Even a mini-mill like Ponderosa Fibers needs 300 tons of straw a day, in order to have 200 tons output.”

A whopping 100 million tons of paper per year are manufactured in America. Conventional raw materials are mainly virgin timber from public and private lands, plus some plantation wood, plus recycled paper, and, imports. Lots of pulp gets imported. Wood for pulping currently fetches $50 to $60 a ton.

For straw, a farmer return of $40 to $45 per ton is feasible, Snyder said. “But it will take a lot of cooperation from farmers within a 70-mile radius of Ponderosa Fiber. A lot of the farmers are skeptical, they see straw pulping as pie-in-the-sky because of failed attempts (to utilize straw industrially) in the past. We’re facing some hard, practical challenges.”

Bill Pan, soil science expert at Washington State University, conducted research of “black liquor” concurrent with Ponderosa Fiber planning for straw use. Black liquor is the term for the spent cooking liquor of the Kraft process of paper making. “The lignins and sugars in black liquor are good for soil structure,” Pan said, noting however that the currently used sodium-based catalyst for pulping renders the black liquor inappropriate for agriculture. “However, if a plant nutrient like ammonium or potassium could be formulated from black liquor, without compromising pulp quality, it would make a good fertilizer. In addition, due to its alkaline nature such a fertilizer could be used as liming agent to offset farming practices that lower the soil pH over time.”

Pan had his hopes up for straw pulping and a resulting black liquor alternative. It would make sense, he put it, “to move ag materials all through the system.”

A nice concept, but...

Tim King of the Carbon Technology Transfer Center in Spokane, Washington summed up the dysfunction of industrial wheat straw: “What's missing is a systems approach."

King had joined the board of Columbia Ag Fiber, a for-profit company that wanted to establish “a biomass waste utilization center” at Lacross, Washington; dubbing straw “biomass waste” was for tax reasons.

King had previously had a 26-year career with the Natural Resource Conservation Service. The NRCS is one of several agencies with a mandate to help wheat and grass seed growers find alternative solutions to field burning.

Adding value is the key to viable straw fiber board production, King pointed out. Specifically, at issue is what to do with low-grade straw, because fiber products that earn an industry rating of Medium Density Fiber – MDF Board the label – are produced only from high quality straw.

Columbia Ag Fiber plans were different from other straw fiber operations in that it would use the estimated 2/3 volume of low-grade straw to produce electricity by gasification. It's a process that subjects straw to a plasma arc in a closed reactor chamber, King explained. "The capacity of the design we're looking at is 12 tons of straw per hour, producing 3/4 million cubic feet of gas – mostly methane which has 760 BTUs per cubic foot. By converting the gas to electricity you get 1 megawatt for every ton of material." There would be no emissions.

The third prong of their systems approach would be necessary for agronomic reasons, King said. As wheat farmers adopt the chemical no-till practice, plant disease cycles have to be prevented by rotational cropping. One of the best options for a chemical no-till rotational crop is canola, since canola seed oil is in constant demand for biodiesel, he noted.

Would there be hurdles? You bet. By 2003 about 20 straw fiber plants existed in the United States and Canada, “but only one of them is successfully operating." In fact, at nearby Plummer, Idaho, a regional straw board plant was built by the Coeur d'Alene Tribe and a small group of grass seed producers in the mid-1990s; they actually developed a market for their product through Home Depot; but Home Depot yielded to pressure from the timber industry and stopped stocking straw fiber board, and that was the end of the Plummer straw plant, King said.

There you have it. Industrial solutions to the wheat straw problem were found, but they either didn’t develop to large enough size, or, enthusiastic big-picture plans petered out in false starts.

Meanwhile the statistics remain mind-boggling: according to the 2003 Bioenergy Inventory and Assessment for Eastern Washington by Ecology, the state's "under-utilized" resources include a yearly supply of 4.3 million tons of dry biomass in Eastern Washington, much of that wheat straw. Ecology figures that this biomass can produce 35 trillion BTUs which could be converted to 3.1 million megawatt hours of electricity.

That's enough power for 40 percent of Eastern Washington residences.

But it’s merely theoretical: “The costs of the collection and transportation of that biomass exceed its energy value.”

The bottom line: only in the fairy tale does straw turn into gold. Think about that the next time you make a straw scarecrow in your garden.

On the surface everything seems alright: a major use for Washington wheat straw is as bedding for livestock, especially dairy cows. Less known but also important is straw for the mushroom industry west of the Cascades, wheat straw the main ingredient of the medium in which the fungi are raised.

Another straw use is by the Forest Service. In the autumn after a forest fire, big straw bales are trucked to a nearby landing. From there the bales are lifted in a net by helicopter and flown to hillsides made vulnerable by the burn. The catch of the net is released and the straw drops toward the steep ground, spreading as it flies. The point of this expensive operation is to reduce erosion. To avoid weed seed spread, the Forest Service sources straw from seed wheat fields that have been certified as weed-free.

So where is the straw problem? The above cited byproduct markets absorb only a small fraction of the straw that needs to be removed from the fields.

Why doesn’t straw stay on the fields? It does, on low-rainfall dryland (dryland receiving less than 12 inches of annual precipitation) all straw is left in the field as a soil building measure. However, on high rainfall dryland and on irrigated acreage the industrial wheats produce too much straw residue, a straw mass so large that it doesn’t break down properly.

Stephen Machado of Oregon State University explained to us that when you grow wheat on wheat, stubble and straw add up to a carbon-nitrogen ratio so high that much of the nitrogen is unavailable to the wheat. In fact, "wheat may become auto-toxic (toxic to itself) in monoculture systems.” This is especially the case in the chemical no-till system that the government currently promotes.

The auto-toxic effect of wheat straw has been known for some time; farmers conventionally resorted to field burning when wheat straw baling was not an option. Back then it was also felt that occasional field burning kept in check some plant diseases and pests.

But in the 1990s the government outlawed most field burning, citing air quality problems caused by the fires.

Whenever government tries to regulate agriculture you get – you guessed it – controversy. Commodity market margins are often so tight that every single field operation needs to pencil out. And now, with field burning restrictions, the government was in effect demanding mechanical straw removal without ready renumeration for the grower.

Across the Pacific Northwest, the field burning controversy resulted in much probing for alternative straw uses.

You’ve heard of straw bale houses? They go back to the first horse-drawn balers of the mid-1800s, said Michael Thomas who together with his wife, Spring Thomas, founded the non-profit IronStraw Group in Ellensburg, Washington. "In Nebraska they invented methods of building with straw bales in areas where the ground was sandy, where there was no sod for building," Thomas elaborated. "Old straw buildings exist in other states, too; a famous one is the Burritt Museum in Huntsville, Alabama that was built as a private home with straw bales in 1938."

The 1970s saw a revival of straw bale construction in the context of the back-to-the-land movement.

As licensed building contractor, Thomas combined straw bale building practicality with 21st-century concepts such as "eco-building," "straw-bale neighborhoods," "nature-based construction." Most famously, he straw-bale-built the Mattawa, Washington public library in 2002.

If Thomas as environmentalist developed good relationships with farmers, those farmers also pointed out soon enough that straw bale building is not likely to amount to much of a straw market, not in the big picture: that Mattawa library, for instance, measures 1500 square feet and required only 310 straw bales. To put that number into a per-acre perspective, consider that three-string straw bale production on an irrigated Spelt field averages over 50 bales to the acre.

Enter David Ward, of Ashland, Oregon. He invented the Strawjet that earned the 2006 Modern Marvel of the Year Award. According to a press release, the panel of experts who judged the submissions from 4300 inventors declared the Strawjet the winner because of its “potential to make a dramatic global impact..."

It certainly is innovative. Ward told us that his Strawjet is a combine-harvester attachment that twists the straw into 2-inch diameter cables, on the go. "They're tightly bundled cables, they're like a round straw bale 2 inches thick. The machine lays down four cables with each pass. The way the hardware is designed, it can also be used as a stand-alone, mounted on a pick-up or tractor," Ward said.

The straw cables stretching across the field are picked up by a "loom machine," he explained. "The loom machine is basically a stack-wagon with a looming mechanism that cuts and weaves the straw cable so it looks like a giant bamboo window blind, each 8 feet long and 5 feet in diameter."

The next step in the process is to infuse the straw weave with a clay-based or cement-based binder. Ward compared the straw weave to the cloth in fiberglass. "It's like making a fiberglass boat, with the mats rolled out."

The final product in the field are building panels 8 feet tall and 14 feet to 16 feet long. These panels are to be loaded by a crane for transport. "Construction with the panels is a lot like construction with cement panels."

Ward envisioned countless uses for Strawjet-generated building materials, especially in Third World countries.

But Chad Kruger, specialist in carbon management issues as director of the Climate-Friendly Farming Project at Washington State University, was skeptical. "In the past there have been myriads of technologies to help poor countries,” Kruger said. “What happens a lot of times is that once the (funded) project goes away, the technology disappears – the real issue is the adoption of technology. One example are the kerosene refrigerators, Third World people just didn't take to that technology."

Closer by, in 2002, hopes for extensive straw use were raised when Ponderosa Fiber was poised to re-open for business as a pilot mill within the large Boise Cascade facility at Wallula, Washington. Bill Snyder, part owner and president of Universal Pulping in Eugene, Oregon was one of the players trying to get the Ponderosa Fiber straw pilot off the ground.

Universal Pulping was founded in 1994, its purpose to “commercialize a novel pulping process called Universal Pulping that uses extremely diluted chemicals,” Snyder said. The new process was initially developed in Europe in the mid-1970s; the patent was awarded to Eric Prior, of West Germany, in 1987.

Universal Pulping differs from conventional paper manufacture – called the Kraft Process – in how the raw fiber is broken down, Snyder elaborated. Whereas the Kraft process requires a “digester” that operates with 100-pound-per-square-inch pressure at temperatures of several hundred degrees Celsius, Universal Pulping requires no pressurizing and creates less heat than boiling.

By implementing the universal pulping technology, Snyder noted, “we believe that the economics work out to where Ponderosa Fiber can operate profitably even in a depressed (pulp) market, at a time when the American paper industry has more capacity than demand. We feel it’s a unique opportunity.” Straw use would be considerable: “Even a mini-mill like Ponderosa Fibers needs 300 tons of straw a day, in order to have 200 tons output.”

A whopping 100 million tons of paper per year are manufactured in America. Conventional raw materials are mainly virgin timber from public and private lands, plus some plantation wood, plus recycled paper, and, imports. Lots of pulp gets imported. Wood for pulping currently fetches $50 to $60 a ton.

For straw, a farmer return of $40 to $45 per ton is feasible, Snyder said. “But it will take a lot of cooperation from farmers within a 70-mile radius of Ponderosa Fiber. A lot of the farmers are skeptical, they see straw pulping as pie-in-the-sky because of failed attempts (to utilize straw industrially) in the past. We’re facing some hard, practical challenges.”

Bill Pan, soil science expert at Washington State University, conducted research of “black liquor” concurrent with Ponderosa Fiber planning for straw use. Black liquor is the term for the spent cooking liquor of the Kraft process of paper making. “The lignins and sugars in black liquor are good for soil structure,” Pan said, noting however that the currently used sodium-based catalyst for pulping renders the black liquor inappropriate for agriculture. “However, if a plant nutrient like ammonium or potassium could be formulated from black liquor, without compromising pulp quality, it would make a good fertilizer. In addition, due to its alkaline nature such a fertilizer could be used as liming agent to offset farming practices that lower the soil pH over time.”

Pan had his hopes up for straw pulping and a resulting black liquor alternative. It would make sense, he put it, “to move ag materials all through the system.”

A nice concept, but...

Tim King of the Carbon Technology Transfer Center in Spokane, Washington summed up the dysfunction of industrial wheat straw: “What's missing is a systems approach."

King had joined the board of Columbia Ag Fiber, a for-profit company that wanted to establish “a biomass waste utilization center” at Lacross, Washington; dubbing straw “biomass waste” was for tax reasons.

King had previously had a 26-year career with the Natural Resource Conservation Service. The NRCS is one of several agencies with a mandate to help wheat and grass seed growers find alternative solutions to field burning.

Adding value is the key to viable straw fiber board production, King pointed out. Specifically, at issue is what to do with low-grade straw, because fiber products that earn an industry rating of Medium Density Fiber – MDF Board the label – are produced only from high quality straw.

Columbia Ag Fiber plans were different from other straw fiber operations in that it would use the estimated 2/3 volume of low-grade straw to produce electricity by gasification. It's a process that subjects straw to a plasma arc in a closed reactor chamber, King explained. "The capacity of the design we're looking at is 12 tons of straw per hour, producing 3/4 million cubic feet of gas – mostly methane which has 760 BTUs per cubic foot. By converting the gas to electricity you get 1 megawatt for every ton of material." There would be no emissions.

The third prong of their systems approach would be necessary for agronomic reasons, King said. As wheat farmers adopt the chemical no-till practice, plant disease cycles have to be prevented by rotational cropping. One of the best options for a chemical no-till rotational crop is canola, since canola seed oil is in constant demand for biodiesel, he noted.

Would there be hurdles? You bet. By 2003 about 20 straw fiber plants existed in the United States and Canada, “but only one of them is successfully operating." In fact, at nearby Plummer, Idaho, a regional straw board plant was built by the Coeur d'Alene Tribe and a small group of grass seed producers in the mid-1990s; they actually developed a market for their product through Home Depot; but Home Depot yielded to pressure from the timber industry and stopped stocking straw fiber board, and that was the end of the Plummer straw plant, King said.

There you have it. Industrial solutions to the wheat straw problem were found, but they either didn’t develop to large enough size, or, enthusiastic big-picture plans petered out in false starts.

Meanwhile the statistics remain mind-boggling: according to the 2003 Bioenergy Inventory and Assessment for Eastern Washington by Ecology, the state's "under-utilized" resources include a yearly supply of 4.3 million tons of dry biomass in Eastern Washington, much of that wheat straw. Ecology figures that this biomass can produce 35 trillion BTUs which could be converted to 3.1 million megawatt hours of electricity.

That's enough power for 40 percent of Eastern Washington residences.

But it’s merely theoretical: “The costs of the collection and transportation of that biomass exceed its energy value.”

The bottom line: only in the fairy tale does straw turn into gold. Think about that the next time you make a straw scarecrow in your garden.

*****

What a long way we’ve come from our Christmas Tree Straw Angel!

But we’re not going to leave you hanging in yet another industrial limbo. ‘Tis the Season to be jolly, so we’ll end the year, and this story, with a cereal food most expressive as holiday accent – a specialty grain green, sweet, and smoked.

Grünkern.

A tradition north of the Alps and in Switzerland, Grünkern – “Green Kernel” in German – is Spelt harvested green, then dried in wood smoke before dehulling.

Chefs love to surprise so they love Grünkern. The goose in the oven, fine veggies sautéing on the stove, and a Grünkern pilaf cooking, what could be a more festive preparation?

Grünkern offers up a unique composition of flavor. Its hint of sweetness stems from the fact that cereal grain is sweet grass, the kernel containing sugars up until the maturing process which turns sugars into carbohydrates (a process exactly the opposite that of tree fruit, the apple’s carbohydrates changing to sugars when ripening). When Spelt is harvested green some of the sugars in the kernel have not yet converted to carbohydrates.

Green grain is much too wet to store. For drying the Grünkern, wood fires were lit in traditional Darren (food dryers), and even today, when innovatively engineered machines are used for curing because the drying in a Darre is much too labor-intensive, wood smoke remains part of the process – the smoked-taste defines Grünkern just as its sweet hint does.

Industrialization almost did away with Spelt, nor did it brook this Grünkern stuff. But just as Spelt enjoyed a reincarnation as a health grain, so Grünkern is experiencing a resurgence, albeit on a yet smaller scale, but reappearing on the top of the specialty food chain.

To learn about Grünkern we travelled to the Bauland of southern Germany where gentle hills roll out a quilt of fields, woods, grazing meadows, small villages nestled in between. We arrived in early July when the Bauland charm remains mostly green, although some of the winter grains have begun ripening to golden yellow of wheat and barley and the golden brown of Spelt, lots of Spelt. Yes, once again more Spelt than wheat is raised in the Bauland, Grünkern production one reason for that.

At Schwabhausen, Dietmar Hofmann was expecting us. Hofmann is tall, of sturdy build, very forthright when he speaks of his Demeter Hof – Hof meaning “farmstead”, Demeter one of several German organic certification organizations, named after the Greek Goddess of grain and fertility.

Schwabhausen is one of the Bauland villages that has preserved its traditional Darre. Hofmann took us there. In the old days you could smell the wood smoke from the Darre throughout the village, an olfactory hallmark of the harvest season, he remarked. Under the roof of the open-sided shed, waist-high stonework embraces a perforated metal pan about 2 square yards in size. For historical accuracy a couple of grain shovels had been placed on the pan; Hofmann explained that the green Spelt had to be turned and shifted throughout the entire smoke-drying process.

But we’re not going to leave you hanging in yet another industrial limbo. ‘Tis the Season to be jolly, so we’ll end the year, and this story, with a cereal food most expressive as holiday accent – a specialty grain green, sweet, and smoked.

Grünkern.

A tradition north of the Alps and in Switzerland, Grünkern – “Green Kernel” in German – is Spelt harvested green, then dried in wood smoke before dehulling.

Chefs love to surprise so they love Grünkern. The goose in the oven, fine veggies sautéing on the stove, and a Grünkern pilaf cooking, what could be a more festive preparation?

Grünkern offers up a unique composition of flavor. Its hint of sweetness stems from the fact that cereal grain is sweet grass, the kernel containing sugars up until the maturing process which turns sugars into carbohydrates (a process exactly the opposite that of tree fruit, the apple’s carbohydrates changing to sugars when ripening). When Spelt is harvested green some of the sugars in the kernel have not yet converted to carbohydrates.

Green grain is much too wet to store. For drying the Grünkern, wood fires were lit in traditional Darren (food dryers), and even today, when innovatively engineered machines are used for curing because the drying in a Darre is much too labor-intensive, wood smoke remains part of the process – the smoked-taste defines Grünkern just as its sweet hint does.

Industrialization almost did away with Spelt, nor did it brook this Grünkern stuff. But just as Spelt enjoyed a reincarnation as a health grain, so Grünkern is experiencing a resurgence, albeit on a yet smaller scale, but reappearing on the top of the specialty food chain.

To learn about Grünkern we travelled to the Bauland of southern Germany where gentle hills roll out a quilt of fields, woods, grazing meadows, small villages nestled in between. We arrived in early July when the Bauland charm remains mostly green, although some of the winter grains have begun ripening to golden yellow of wheat and barley and the golden brown of Spelt, lots of Spelt. Yes, once again more Spelt than wheat is raised in the Bauland, Grünkern production one reason for that.

At Schwabhausen, Dietmar Hofmann was expecting us. Hofmann is tall, of sturdy build, very forthright when he speaks of his Demeter Hof – Hof meaning “farmstead”, Demeter one of several German organic certification organizations, named after the Greek Goddess of grain and fertility.

Schwabhausen is one of the Bauland villages that has preserved its traditional Darre. Hofmann took us there. In the old days you could smell the wood smoke from the Darre throughout the village, an olfactory hallmark of the harvest season, he remarked. Under the roof of the open-sided shed, waist-high stonework embraces a perforated metal pan about 2 square yards in size. For historical accuracy a couple of grain shovels had been placed on the pan; Hofmann explained that the green Spelt had to be turned and shifted throughout the entire smoke-drying process.

And wood had to be fed continuously, too, into the furnace of the stone understory, the stone steps leading down well-worn.

No one knows the origin of Grünkern. Archeobotanists state that no clear evidence of prehistoric green-grain harvests has been found, however, since some of their finds consist of kernels shriveled and caramelized, they cannot rule out that something like Grünkern production was practiced at the dawn of agriculture. The fact is that Frikeh, a green durum wheat product similar to Grünkern, is a very old tradition in several Near East countries. Does this green-harvest tradition stretch back to the pre-agrarian epoch? We’ll probably never know for sure.

First written accounts of German Grünkern appear in documents from the 1600s, indicating it was already an old custom then to smoke green Spelt. As farmer, Hofmann looks to the skies for clues – blue sky where the sun shines but a threatening dark under tall balling thunderheads. Clearly those clouds spell danger for ripe fields dry and brittle, destruction by hail or lightening strike always a possibility in the Bauland summers. Hofmann’s hypothesis is that Grünkern originated as a means to spread risk: the earlier the harvest, the less risk to the village food supply. Also, by cutting some of the fields green, the harvest period was extended.

That the smoked green Spelt delights the taste buds was a special bonus.

No one knows the origin of Grünkern. Archeobotanists state that no clear evidence of prehistoric green-grain harvests has been found, however, since some of their finds consist of kernels shriveled and caramelized, they cannot rule out that something like Grünkern production was practiced at the dawn of agriculture. The fact is that Frikeh, a green durum wheat product similar to Grünkern, is a very old tradition in several Near East countries. Does this green-harvest tradition stretch back to the pre-agrarian epoch? We’ll probably never know for sure.

First written accounts of German Grünkern appear in documents from the 1600s, indicating it was already an old custom then to smoke green Spelt. As farmer, Hofmann looks to the skies for clues – blue sky where the sun shines but a threatening dark under tall balling thunderheads. Clearly those clouds spell danger for ripe fields dry and brittle, destruction by hail or lightening strike always a possibility in the Bauland summers. Hofmann’s hypothesis is that Grünkern originated as a means to spread risk: the earlier the harvest, the less risk to the village food supply. Also, by cutting some of the fields green, the harvest period was extended.

That the smoked green Spelt delights the taste buds was a special bonus.

*****

When we get to Hofmann’s farm we see that it’s a large operation by Franconian standards. The family raises 90 milk cows; on 540 acres, some of which he leases, Hofmann grows hay, spelt, rye, barley and triticale, and some acres he manages as grazing meadows that are dotted with free-standing cider-apple trees, called Streuobst, “strewn fruit.”

The farm had a modest start in 1950 when his grandfather built a shed for the hay he raised on about 12 acres. “He milked four cows, and he raised hogs,” Hofmann related.

As their Hof prospered over the years, the family expanded their operations. In the mid-1980s they transitioned to organic: “Demeter defines a system of biodynamic farming that’s the highest level of (German) organic agriculture,” Hofmann put it.

The Spelt we’ve come to see he grows on 120 acres, of which 54 acres are designated for Grünkern.

It turned out that we’d made the trip just in time, this was the last day of wood-smoke-drying the Grünkern crop. Hofmann began the tour by a large shed where cord wood was stacked high. “We use oak and beech, because they’re hardwood. Hardwood has good flavor, and it’s safer to burn, it throws less sparks.”

The furnace of stone holds two cubic yards of cord wood, Hofmann explained. A thermometer prominently mounted tracks the temperature which ranges from 320 degrees to 400 degrees Fahrenheit. Per batch measuring 11 cubic yards it takes four to six hours to reduce the moisture from 40 to 50 percent in the green Spelt, to 10 to 12 percent moisture of Gruenkern.

In the adjoining shed section, hefty electric motors power blowers that force the hot air from the furnace into a system of big ducts connected to a tall apparatus. It looks like a metal tower, this modern Darre about 10 yards tall, 2 yards wide and 2 yards deep.

The inside of the structure consists of triangular shafts in the shape of long troughs, small triangle openings for fresh air at their ends. The trough-shaped shafts turn slowly.

Hofmann showed us how the green Spelt – still in the hull – gets transported to the top of this modern Darre by an elevator, the green grain dropping slowly through the layers of shafts as they turn. The grain that’s arrived at the bottom is moved by an augur over to the elevator, and carried back up to the top for its next journey down through the Darre.

The farm had a modest start in 1950 when his grandfather built a shed for the hay he raised on about 12 acres. “He milked four cows, and he raised hogs,” Hofmann related.

As their Hof prospered over the years, the family expanded their operations. In the mid-1980s they transitioned to organic: “Demeter defines a system of biodynamic farming that’s the highest level of (German) organic agriculture,” Hofmann put it.

The Spelt we’ve come to see he grows on 120 acres, of which 54 acres are designated for Grünkern.

It turned out that we’d made the trip just in time, this was the last day of wood-smoke-drying the Grünkern crop. Hofmann began the tour by a large shed where cord wood was stacked high. “We use oak and beech, because they’re hardwood. Hardwood has good flavor, and it’s safer to burn, it throws less sparks.”

The furnace of stone holds two cubic yards of cord wood, Hofmann explained. A thermometer prominently mounted tracks the temperature which ranges from 320 degrees to 400 degrees Fahrenheit. Per batch measuring 11 cubic yards it takes four to six hours to reduce the moisture from 40 to 50 percent in the green Spelt, to 10 to 12 percent moisture of Gruenkern.

In the adjoining shed section, hefty electric motors power blowers that force the hot air from the furnace into a system of big ducts connected to a tall apparatus. It looks like a metal tower, this modern Darre about 10 yards tall, 2 yards wide and 2 yards deep.

The inside of the structure consists of triangular shafts in the shape of long troughs, small triangle openings for fresh air at their ends. The trough-shaped shafts turn slowly.

Hofmann showed us how the green Spelt – still in the hull – gets transported to the top of this modern Darre by an elevator, the green grain dropping slowly through the layers of shafts as they turn. The grain that’s arrived at the bottom is moved by an augur over to the elevator, and carried back up to the top for its next journey down through the Darre.

*****

To see a modern Darre of different design, Hofmann leads us to his neighbor’s Hof. Here, too, the furnace is separated from the blowers by a wall; the green Spelt moves through a long metal drum horizontally aligned, open-topped, a succession of turning bars shuttling the drying grain from one end to the other, similar to how a debearder moves grain.

As we admire the inventiveness of these modern Darre, Hofmann makes a shoveling gesture to remind us of the incentive for such ingenuity – the chore of turning grain layers on the traditional Darre with shovels, that must have been one hard, hot, long job. Then and now, Hofmann pointed out, “Grünkern production is around-the-clock work for about two weeks.”

He reached in the Darre for a handful of the green Spelt. With his fingernails he pried a few kernels from the hulls, to show us the green coloring. “That’s what the market wants, that green color. If it’s harvested just a touch later, it’s as good tasting a product, but because it’s called Grünkern, people want it green.”

How does he determine the harvest date?

“Let’s go to the fields.”

As we admire the inventiveness of these modern Darre, Hofmann makes a shoveling gesture to remind us of the incentive for such ingenuity – the chore of turning grain layers on the traditional Darre with shovels, that must have been one hard, hot, long job. Then and now, Hofmann pointed out, “Grünkern production is around-the-clock work for about two weeks.”

He reached in the Darre for a handful of the green Spelt. With his fingernails he pried a few kernels from the hulls, to show us the green coloring. “That’s what the market wants, that green color. If it’s harvested just a touch later, it’s as good tasting a product, but because it’s called Grünkern, people want it green.”

How does he determine the harvest date?

“Let’s go to the fields.”

*****

The combine harvesters we see on the way are John Deere and Claas. Green Spelt can be harvested by any type of modern combine, Hofmann said. The only slight difference between harvesting Spelt green and Spelt ripe is that with green Spelt one or two spikelets at the bottom of the grain head tend to cling to the stalk.

Before the invention of combines, stands of green Spelt were cut with scythes, then the spikelets were separated by pulling the grain heads through comb-like rakes. As for the dehulling, in the old days the millers did that with special types of grind stones, Hofmann noted.

From grain heads he’d gathered from adjoining fields while we walked along, he now squeezed the spikelets between thumb and forefinger, showing us the “milk stage” of maturity – “the inner part of the grain is almost fluid, it squirts, when it squirts it’s too early to harvest.” Next the kernel matures to the “dough stage” when the green grain feels sluggishly squishy, a little like dough. “That’s when you harvest for Grünkern, in the dough stage.”

Before the invention of combines, stands of green Spelt were cut with scythes, then the spikelets were separated by pulling the grain heads through comb-like rakes. As for the dehulling, in the old days the millers did that with special types of grind stones, Hofmann noted.

From grain heads he’d gathered from adjoining fields while we walked along, he now squeezed the spikelets between thumb and forefinger, showing us the “milk stage” of maturity – “the inner part of the grain is almost fluid, it squirts, when it squirts it’s too early to harvest.” Next the kernel matures to the “dough stage” when the green grain feels sluggishly squishy, a little like dough. “That’s when you harvest for Grünkern, in the dough stage.”

Hot days make for fast ripening, so the ripe Spelt – locally called Dinkel – gets harvested right after the green Spelt has been cut and smoked.

We asked about varietal differences. Despite industrialization, a great number genotypes of the formally dominant bread grain survived in central Europe. “In Switzerland alone they still have over 100 Spelt varieties."

The acres Hofmann designates for Dinkel he plants to Oberkulmer and Frankenkorn Spelt; for his Grünkern he sticks with the local genotype Baulander Spelz. The Baulander, he remarked, stools out the best, he’s counted as many as 26 tillers on Baulander plants.

For a minute we watched with Hofmann how the afternoon breeze made sway in his summer grains. Then he launched into a talk about his Demeter system, passionately so – “es ist wunderbar!” In total contrast to industrial agriculture and its linear logic, Demeter farm practice knits together the various components in circular fashion. The manure from his dairy cattle isn’t a liability but adequate fertilizer. For hay he raises clover and alfalfa that also add nitrogen to his soils. “I grow Spelt in rotation after clover,” Hofmann said, noting that his ripe Spelt tests between 14 and 16 percent protein.

Not that it’s easy to arrive at a crop-and-livestock harmony, he emphasized. “You have to plan years ahead to make it work.”

Demand for Grünkern has rebounded to where a Grünkern growers association was formed, now numbering 40 member growers. “Prices for fuel and machinery keep going up. The price for Grünkern has been €70 per 100 kilogram for Grünkern in the hull (about $0.24 a pound American). Our association is asking for a better price.”

We asked about varietal differences. Despite industrialization, a great number genotypes of the formally dominant bread grain survived in central Europe. “In Switzerland alone they still have over 100 Spelt varieties."

The acres Hofmann designates for Dinkel he plants to Oberkulmer and Frankenkorn Spelt; for his Grünkern he sticks with the local genotype Baulander Spelz. The Baulander, he remarked, stools out the best, he’s counted as many as 26 tillers on Baulander plants.

For a minute we watched with Hofmann how the afternoon breeze made sway in his summer grains. Then he launched into a talk about his Demeter system, passionately so – “es ist wunderbar!” In total contrast to industrial agriculture and its linear logic, Demeter farm practice knits together the various components in circular fashion. The manure from his dairy cattle isn’t a liability but adequate fertilizer. For hay he raises clover and alfalfa that also add nitrogen to his soils. “I grow Spelt in rotation after clover,” Hofmann said, noting that his ripe Spelt tests between 14 and 16 percent protein.

Not that it’s easy to arrive at a crop-and-livestock harmony, he emphasized. “You have to plan years ahead to make it work.”

Demand for Grünkern has rebounded to where a Grünkern growers association was formed, now numbering 40 member growers. “Prices for fuel and machinery keep going up. The price for Grünkern has been €70 per 100 kilogram for Grünkern in the hull (about $0.24 a pound American). Our association is asking for a better price.”

*****

We followed a tractor-pulled wagon loaded with Hofmann’s Grünkern to Boxberg, 3 miles from the farm. There the Bauland Grünkern is received at the facility of the Zentralgenossenschaft (ZG) Raiffeisen, a large farm supply and commodity marketing company that operates along a large swath of southern Germany.

The Boxberg warehouse is a one-man operation, Gerald Gatzstatter that man. “This facility was outfitted with special equipment just for spelt in 1989,” he noted.

The growers unload into a pit under cover. Belts and elevators move the grain into the building where more elevators and belts keep the flow going as six machines each do their specific job in the dehulling process.

“The first machine is a de-stoner. Next is the impact dehuller,” Gatzstatter said. Next, the mass of empty hulls is removed from the flow by a winnowing machine, then a screen mill separates the material by size, then an indent diverts cracked grain and other fines, and the gravity deck does the final separation by weight.

“Dinkel runs at about 2 tons per hour. Running Grünkern is slower, about 1 ton per hour. I get 70 percent clean-out, by weight,” Gatzstatter noted. The finished product is stored in 220-pound grain sacks.

As for the marketing, we’re directed to speak with Peter Frey at the ZG office a couple of miles down the road.

Compared to the big commodities such as wheat and barley which are their main marketing focus, Grünkern ranks rather minuscule, Frey stressed. “It’s a very, very small market.”

Ironically, the early phase of industrialization boosted Grünkern production, the railroads opening up trade corridors just as soup processing progressed. Knorr, a well-known company to this day, bought and sold Grünkern starting in 1867, and in 1872 began producing soups with Grünkern flour. This heralded the heyday of Franconian Grünkern – up to World War One about 6000 tons were shipped annually. By World War Two that tonnage had shrunk to about half, and by the 1980s Grünkern production had slimmed from the 6500 acres of its glory days to 600 acres. Since, a slow rebound, with currently about 15 of the traditional 90 Grünkerndörfer again smoking green spelt.

“About 90 percent of our Grünkern sales are to firms that process it. A lot is used in soups, some goes for making Bratlinge (vegetarian Hamburgers), and some is used by bakeries,” Frey said.

Grünkern shipments from ZG indicate a steady business in Europe. “We ship Grünkern to Switzerland, Holland, Belgium, Italy.”

The Boxberg warehouse is a one-man operation, Gerald Gatzstatter that man. “This facility was outfitted with special equipment just for spelt in 1989,” he noted.

The growers unload into a pit under cover. Belts and elevators move the grain into the building where more elevators and belts keep the flow going as six machines each do their specific job in the dehulling process.

“The first machine is a de-stoner. Next is the impact dehuller,” Gatzstatter said. Next, the mass of empty hulls is removed from the flow by a winnowing machine, then a screen mill separates the material by size, then an indent diverts cracked grain and other fines, and the gravity deck does the final separation by weight.

“Dinkel runs at about 2 tons per hour. Running Grünkern is slower, about 1 ton per hour. I get 70 percent clean-out, by weight,” Gatzstatter noted. The finished product is stored in 220-pound grain sacks.

As for the marketing, we’re directed to speak with Peter Frey at the ZG office a couple of miles down the road.

Compared to the big commodities such as wheat and barley which are their main marketing focus, Grünkern ranks rather minuscule, Frey stressed. “It’s a very, very small market.”

Ironically, the early phase of industrialization boosted Grünkern production, the railroads opening up trade corridors just as soup processing progressed. Knorr, a well-known company to this day, bought and sold Grünkern starting in 1867, and in 1872 began producing soups with Grünkern flour. This heralded the heyday of Franconian Grünkern – up to World War One about 6000 tons were shipped annually. By World War Two that tonnage had shrunk to about half, and by the 1980s Grünkern production had slimmed from the 6500 acres of its glory days to 600 acres. Since, a slow rebound, with currently about 15 of the traditional 90 Grünkerndörfer again smoking green spelt.

“About 90 percent of our Grünkern sales are to firms that process it. A lot is used in soups, some goes for making Bratlinge (vegetarian Hamburgers), and some is used by bakeries,” Frey said.

Grünkern shipments from ZG indicate a steady business in Europe. “We ship Grünkern to Switzerland, Holland, Belgium, Italy.”

*****

For us, Grünkern was a becoming topic as the New Year approaches. For 12 months we’ve tracked the journey of Einkorn and its ancient cohorts, temporally in the field at the Lentz Farm, history-wise in Kurdistan and across Europe. We’ve drank Einkorn Bier and eaten Bere bannocks – the resurgence is on, folks!

Slow Food promotion of Grünkern speaks of the cereal specialty as “noble.” Indeed, the more that the industries of war steamroll toward homogenized food control of the world, the more do resurgent heritage crops and integral farming systems become ennobling.

Einkorn opened the flood gates to civilization when it domesticated the human species. At the end of the story we must acknowledge that Einkorn, emblematic of true food as it is, and precisely because it fits so well into progressive organic farming, offers us a way to an agriculture more sane, agrarian, locally simple, simply better.

Let terroir into your kitchen. Savor the land-races.

Long live the Bon in Bon Appétit!

Slow Food promotion of Grünkern speaks of the cereal specialty as “noble.” Indeed, the more that the industries of war steamroll toward homogenized food control of the world, the more do resurgent heritage crops and integral farming systems become ennobling.

Einkorn opened the flood gates to civilization when it domesticated the human species. At the end of the story we must acknowledge that Einkorn, emblematic of true food as it is, and precisely because it fits so well into progressive organic farming, offers us a way to an agriculture more sane, agrarian, locally simple, simply better.

Let terroir into your kitchen. Savor the land-races.

Long live the Bon in Bon Appétit!

© 2013 Lentz Spelt Farms

RSS Feed

RSS Feed