For a printable version of the newsletter, click here.

Hi there, Einkorn here.

Einkorn standing up: in May the grain crops on the Columbia Plateau rise from the two-dimensional quilt of fallow fields brown and planted fields flat green, to where the green acres acquire their third dimension. And so the waves begin again, the ripple and swell of tall grass in the wind, an undulating pompadour of growth a-stretching stems.

No longer do Farrow fields resemble wheat, industrial wheat only gets to its knees while the Farrow grains grow proud and tall at Lentz Spelt Farms.

The last leaf the plant grows, the largest leaf highest up, is called the flag leaf. The term fits – when that flag leaf appears the stand does look like a million green flags waving. The flag leaf functions as solar sail gathering strength for the plant’s reproductive phase.

Hi there, Einkorn here.

Einkorn standing up: in May the grain crops on the Columbia Plateau rise from the two-dimensional quilt of fallow fields brown and planted fields flat green, to where the green acres acquire their third dimension. And so the waves begin again, the ripple and swell of tall grass in the wind, an undulating pompadour of growth a-stretching stems.

No longer do Farrow fields resemble wheat, industrial wheat only gets to its knees while the Farrow grains grow proud and tall at Lentz Spelt Farms.

The last leaf the plant grows, the largest leaf highest up, is called the flag leaf. The term fits – when that flag leaf appears the stand does look like a million green flags waving. The flag leaf functions as solar sail gathering strength for the plant’s reproductive phase.

The grain head grows in a thickening roll, developing while the stem lifts above the flag leaf until the head’s formed its characteristic shape. And one day in May the bloom commences. You have to look closely to see tiny threads of anthers protruding in vertical rows from the green head. Since cereal grains don’t rely on insects for pollination, this bloom doesn’t advertise but it’s powerful in that pollination happens completely, a kernel to grow where a kernel can grow thanks to the plant’s self-pollinating habit.

In good weather, that is. Frost can still happen in May, frost too coarse for the sensitive bloom, frost that diminishes the crop. If frost and cold are prolonged in May, at the farmstead the phoebe chicks die in their nests because the parent birds cannot find flying insects. The phoebes then will breed again to raise a second brood. Conversely, the cereal plant offers up but one bloom.

When it rains – if it rains – in May you can look forward to plump kernels. But in years when sparse April rain is followed by an arid May and then a rainless June, plant stress accumulates to the point where the kernels shrivel. It’s still a crop to harvest but by volume – bushels – it’ll be a light crop.

It’s always been thus, the farmer hoping, praying, perhaps even dancing for rain at the right time. Or, praying for a drying sun in wet regions cloud-besieged. After all, Einkorn was moving into many lands of many climates, soon after it had put to use the uncouth animals out of Africa who wandered hither and thither on two legs, after it had coaxed them with easy carbohydrates to spread Einkorn seed far and wide.

Early during Einkorn’s march an Armenian plant felt the stirring of opportunity. North-east of Turkey’s Karaca Dag shield volcano where Einkorn evolved, Armenia, with its highlands, was a favorite passage for the wanderers – here humans invented the shoe. (Well, it’s here that archeologists found the oldest shoe.)

The humans carried with them quite the little party of grasses. Einkorn had been accompanied by its daughter Emmer when oat and rye committed mimicry to join up, while goatgrass snuck in doggedly, intent to outcross, which it did eventually and so offspring Spelt, too, moved along with the group.

Our Armenian plant must have been astonished by this procession of grasses. Not a grass itself, its opportunity to attach itself to this band of grasses lay in the size of its seed, so tiny that 400,000 seeds weigh less than a pound. When you’re as small as that it’s easy to slip into the stream of species spread.

Camelina is the name of our Armenian friend. Belonging to the genus Brassica – cabbage, turnip, Brussels sprout, mustard among its relatives –, Camelina exhibited disposition to camaraderie. A psychologist would give it a plays-well-with-others rating.

Physically, Camelina is a plant that starts growth by hugging the ground as a horizontal rosette, from which bolts a modest stalk that spreads out laterals bearing placid yellow flowers – not a screaming yellow like rapeseed. Camelina flowers on their thin stems, in aggregate emit a distinct smell similar to broccoli cooking. In maturing Camelina dries up to ochre after the flowers turned into pods wherein rattle around six to a dozen seeds.

By the time our band of plants arrived in Western Europe it had been joined by pulses as well – lentil, pea and such –, so when archeologists like Julian Wiethold dig and scratch and find evidence of the first human settlements in France, they invariably unearth a harvest mixture that the ancients had learned to bury in underground food storage pits. The conclusion: these crops were raised mixed together, in what German agriculturists call Mischkultur. Or, if you prefer those long German words, call the farming system Mischfruchtanbau and let your tongue wobble.

In good weather, that is. Frost can still happen in May, frost too coarse for the sensitive bloom, frost that diminishes the crop. If frost and cold are prolonged in May, at the farmstead the phoebe chicks die in their nests because the parent birds cannot find flying insects. The phoebes then will breed again to raise a second brood. Conversely, the cereal plant offers up but one bloom.

When it rains – if it rains – in May you can look forward to plump kernels. But in years when sparse April rain is followed by an arid May and then a rainless June, plant stress accumulates to the point where the kernels shrivel. It’s still a crop to harvest but by volume – bushels – it’ll be a light crop.

It’s always been thus, the farmer hoping, praying, perhaps even dancing for rain at the right time. Or, praying for a drying sun in wet regions cloud-besieged. After all, Einkorn was moving into many lands of many climates, soon after it had put to use the uncouth animals out of Africa who wandered hither and thither on two legs, after it had coaxed them with easy carbohydrates to spread Einkorn seed far and wide.

Early during Einkorn’s march an Armenian plant felt the stirring of opportunity. North-east of Turkey’s Karaca Dag shield volcano where Einkorn evolved, Armenia, with its highlands, was a favorite passage for the wanderers – here humans invented the shoe. (Well, it’s here that archeologists found the oldest shoe.)

The humans carried with them quite the little party of grasses. Einkorn had been accompanied by its daughter Emmer when oat and rye committed mimicry to join up, while goatgrass snuck in doggedly, intent to outcross, which it did eventually and so offspring Spelt, too, moved along with the group.

Our Armenian plant must have been astonished by this procession of grasses. Not a grass itself, its opportunity to attach itself to this band of grasses lay in the size of its seed, so tiny that 400,000 seeds weigh less than a pound. When you’re as small as that it’s easy to slip into the stream of species spread.

Camelina is the name of our Armenian friend. Belonging to the genus Brassica – cabbage, turnip, Brussels sprout, mustard among its relatives –, Camelina exhibited disposition to camaraderie. A psychologist would give it a plays-well-with-others rating.

Physically, Camelina is a plant that starts growth by hugging the ground as a horizontal rosette, from which bolts a modest stalk that spreads out laterals bearing placid yellow flowers – not a screaming yellow like rapeseed. Camelina flowers on their thin stems, in aggregate emit a distinct smell similar to broccoli cooking. In maturing Camelina dries up to ochre after the flowers turned into pods wherein rattle around six to a dozen seeds.

By the time our band of plants arrived in Western Europe it had been joined by pulses as well – lentil, pea and such –, so when archeologists like Julian Wiethold dig and scratch and find evidence of the first human settlements in France, they invariably unearth a harvest mixture that the ancients had learned to bury in underground food storage pits. The conclusion: these crops were raised mixed together, in what German agriculturists call Mischkultur. Or, if you prefer those long German words, call the farming system Mischfruchtanbau and let your tongue wobble.

*****

Julian Wiethold was a speaker at one of a series of Camelina forums held at baroque Blieskastel in Germany’s Saarland. The surrounding Bliesgau is an area where you best tread lightly since 2009, when UNESCO declared it a Biosphere, one of 610 worldwide. Appropriate then that this year’s Camelina forum focused on Naturnahem Anbau – “Nature-Near Farming.” The forum Wiethold spoke at a couple of years ago was heralded as International Kongress Zum Öl der Kelten, celebrating the “Oil of the Celts.” Camelina growers from as far away as Mongolia attended.

Wiethold’s lecture started with acknowledgment that Camelina traveled as weed from the 6th millennium B.C. on, before agrarians discovered the fine traits of its oil. In Armenia it was still the wild form, Camelina microcarpa, that would embrace Europe from Greece to Scandinavia, from the 5th to the 3rd millennium. “Archeological finds of Camelina become frequent in the 2nd millennium B.C.,” Wiethold said, indication that peoples had begun using the oil.

Europe’s domesticated Camelina sativa interacted predominantly with grain and pulse crops. Later a Camelina subpopulation chose flax for a companion crop and metamorphosed to Camelina alyssum. This explains the main German word for Camelina, Leindotter (Lein means “flax”). Other Camelina species identified are C. anomala, C. asiocarpa, C. hispida, C. laxa, all of them found in Turkey and points east. Southeast Europe’s Camelina rumelica grows wild, according to Wiethold.

“Camelina had become an immensely important crop in the younger Bronze Age, around 1200 B.C.,” he noted. But archeology can not explain how the oil was processed: “Fire seems to have played a role; clumps of carbonized Camelina seeds are the archeological evidence.”

Western France, especially in the north, yields evidence of extended Camelina presence in Mischkultur at the time when West European civilizations first achieved size, Wiethold noted. “Major settlements with central crop storage and distribution existed as far back as 500 B.C. The evidence are huge fields of Speichergruben (silo pits) measuring up to 3600 liters in volume” (about 950 gallons).

Wiethold divines that farmers then had a good knowledge of soils, because not all ground was suitable for silo pits. Incidentally, there are parallels between those silo pits and the Controlled Atmosphere apple storage technology introduced around 1960, namely that oxygen is replaced: “The silo pits had their atmosphere controlled by the carbon dioxide emitted by the stored grain spikelets,” Wiethold elaborated. “Obviously, this helped a lot against insects, but not totally against fungi.”

Once opened, the Speichergrube would have been emptied of all the grain/lentil/Camelina mixed-crop; to keep it from spoiling it would then have been stored in earthenware, probably. Of grains only the hulled types have been found at digs of this early period, so the post-storage chore of dehulling and cleaning the Einkorn, Emmer and Spelt was a long and complex process, Wiethold elaborated. First the grain was threshed with cudgel-like flails, then winnowed, then the glumes were de-husked with stone querns – hand mills – or some kind of mortar-and-pestle method; another winnowing followed before the clean grain was gained at last.

Among the mixed crops of Europe's late Bronze Age and early Iron Age, from 800 B.C. on, oil crops included hemp, poppy, flax, with Camelina clearly the most important in some coastal regions, perhaps due to the species’ relative salt tolerance, Wiethold said.

Why Camelina’s heyday waned remains a mystery, he noted. “After the Roman occupation of Gaul (a.k.a. Celtica) the great era of Camelina came to an end.” One theory has it that the then-expanding Roman trade in olive oil was one of the causes, he said.

If not as major crop, Camelina remained important to European agriculture through the ages. In 1546, Hieronymus Bock praised the Saarland Camelina oil as lieblich – “dear, lovely” – in his botanical writings.

In 19th-century France a Camelina production of about 15,000 acres was documented before decline began; in Eastern Europe and Asia, Camelina farming continued strong up to mid-20th century, Wiethold said.

Wiethold’s lecture started with acknowledgment that Camelina traveled as weed from the 6th millennium B.C. on, before agrarians discovered the fine traits of its oil. In Armenia it was still the wild form, Camelina microcarpa, that would embrace Europe from Greece to Scandinavia, from the 5th to the 3rd millennium. “Archeological finds of Camelina become frequent in the 2nd millennium B.C.,” Wiethold said, indication that peoples had begun using the oil.

Europe’s domesticated Camelina sativa interacted predominantly with grain and pulse crops. Later a Camelina subpopulation chose flax for a companion crop and metamorphosed to Camelina alyssum. This explains the main German word for Camelina, Leindotter (Lein means “flax”). Other Camelina species identified are C. anomala, C. asiocarpa, C. hispida, C. laxa, all of them found in Turkey and points east. Southeast Europe’s Camelina rumelica grows wild, according to Wiethold.

“Camelina had become an immensely important crop in the younger Bronze Age, around 1200 B.C.,” he noted. But archeology can not explain how the oil was processed: “Fire seems to have played a role; clumps of carbonized Camelina seeds are the archeological evidence.”

Western France, especially in the north, yields evidence of extended Camelina presence in Mischkultur at the time when West European civilizations first achieved size, Wiethold noted. “Major settlements with central crop storage and distribution existed as far back as 500 B.C. The evidence are huge fields of Speichergruben (silo pits) measuring up to 3600 liters in volume” (about 950 gallons).

Wiethold divines that farmers then had a good knowledge of soils, because not all ground was suitable for silo pits. Incidentally, there are parallels between those silo pits and the Controlled Atmosphere apple storage technology introduced around 1960, namely that oxygen is replaced: “The silo pits had their atmosphere controlled by the carbon dioxide emitted by the stored grain spikelets,” Wiethold elaborated. “Obviously, this helped a lot against insects, but not totally against fungi.”

Once opened, the Speichergrube would have been emptied of all the grain/lentil/Camelina mixed-crop; to keep it from spoiling it would then have been stored in earthenware, probably. Of grains only the hulled types have been found at digs of this early period, so the post-storage chore of dehulling and cleaning the Einkorn, Emmer and Spelt was a long and complex process, Wiethold elaborated. First the grain was threshed with cudgel-like flails, then winnowed, then the glumes were de-husked with stone querns – hand mills – or some kind of mortar-and-pestle method; another winnowing followed before the clean grain was gained at last.

Among the mixed crops of Europe's late Bronze Age and early Iron Age, from 800 B.C. on, oil crops included hemp, poppy, flax, with Camelina clearly the most important in some coastal regions, perhaps due to the species’ relative salt tolerance, Wiethold said.

Why Camelina’s heyday waned remains a mystery, he noted. “After the Roman occupation of Gaul (a.k.a. Celtica) the great era of Camelina came to an end.” One theory has it that the then-expanding Roman trade in olive oil was one of the causes, he said.

If not as major crop, Camelina remained important to European agriculture through the ages. In 1546, Hieronymus Bock praised the Saarland Camelina oil as lieblich – “dear, lovely” – in his botanical writings.

In 19th-century France a Camelina production of about 15,000 acres was documented before decline began; in Eastern Europe and Asia, Camelina farming continued strong up to mid-20th century, Wiethold said.

*****

Let’s take a break from Blieskastel and jump to the America of industrialized mass production. From here Camelina was shunted aside because its oil does not lend itself to hydrogenation. Ironic, isn’t it, that an oil high in omega 3 and antioxidants such as Camelina would be side-lined until science – rather belatedly! – established that the industry-touted hydrogenated-oil transfats contribute to heart disease.

Initially, though, not revelations about transfats but biofuel issues shed light on a possible Camelina resurgence in the United States. In the 1990s, Montana State University researcher Duane Johnson had been working with a group of growers to establish a canola program with an eye on biodiesel. (Canola is the result of a Canadian plant breeding program that removed most of the erucic acid from rapeseed; in Europe canola is known as “zero-zero rape.”) Johnson just couldn’t get the numbers to work; on the dryland east of the Rockies, canola yields were poor mostly. Johnson diverted the project to biolubricant production because returns on biolubricants are a little better than on biofuel, but that went nowhere when industry threw up political hurdles. Then Johnson read European Union reports investigating a range of oil plants for their suitability in biofuel production. What he found out about Camelina excited him.

Alright, Johnson is an excitable fellow. You wouldn’t describe him as wiry, but he acts wiry; once he’s wormed his way through an enigma he sets out to turn anyone who’ll listen into a believer of a new paradigm. Johnson thinks on his feet: once a skeptical journalist asked to take a photo of him, whereupon Johnson led the man to the pick-up truck of the research station, opened the hood to pull the dipstick from the oil pan – and proceeded to lick the dipstick, with wink and flair no less, proclaiming: “It’s just vegetable oil!” That was one photo surely worth a thousand words.

In research trials Johnson confirmed that Camelina, an undemanding and pest resistant crop cheap to seed, would produce a much better return for the farmer than rapeseed/canola, specifically in marginal growing regions like semi-arid, cold Eastern Montana. "Canola requires $100 to $110 input per acre, including five to six trips across the field, whereas Camelina requires very low input, $45 to $65 per acre. It grows like a weed – you throw the seed on the ground, walk away and don't come back until it's ready to combine," Johnson put it, speaking in 2006.

Camelina is facultative in growth habit, so it can be seeded over a long period. "We've had good results broadcasting the seed as soon as the ground's bare of snow," Johnson said. "When planted into wheat and barley stubble, it controls the volunteers as well as the weeds, it's very allelopathic." Thus Camelina has dryland rotation crop advantages, including the fact that the seed has zero dormancy (no delayed sprouting).

"On Eastern Montana acreage with 10 to 12 inches effective rainfall, Camelina has yielded around 1500 pounds per acre," Johnson said.

With his biofuel focus, Johnson liked to emphasize Camelina use by the ancients as lamp oil. Looking forward, he expected the omega 3 content in Camelina to play a role in its market development. He quoted from medical research pertaining to omega 3 unsaturated fatty acids, that they can reduce inflammation linked to heart disease, stroke, diabetes, arthritis, and other human illness. For these reasons we’re advised to eat ocean fish, he explained. "Phytoplankton in the oceans make omega 3. As the omega 3s move through the food chain they become more concentrated, and cold water fish rely on them for survival in cold climates."

Ah, but there is a global problem, namely species-threatening harvest levels of wild fish stocks, a disastrous course in part blamed on rising omega 3 demand, Johnson said: that’s why the Camelina resurgence has appeal for environmentalists. Not only is cold-pressed Camelina oil a fine food product – think salad oil –, but after biofuel crushing the press cake that still contains good levels of omega 3 can be fed to livestock. A trial was underway to see if feeding Camelina at fish farms would result in omega 3 farmed fish.

Further health benefits of Camelina oil lie in its a cholesterol-reducing effect, according to a Danish study.

Not long, though, and Johnson harked back to his biofuel focus. Which wasn’t hard to do, what with all those semi-trucks blowing by on the highway in front of his office window. Belching sulfur, he emphasized, was one health-damaging aspect of diesel motors: “The sulfur is added as lubricant. Adding 2 percent biodiesel to diesel is one way to replace sulfur as lubricant."

Big industry has big plans for biodiesel, Johnson said. "ADM wants to expand their biodiesel production in the Midwest to 100 million gallons a year." A byproduct when making soybean oil into biodiesel is glycerin. "ADM alone will produce enough glycerin to cover the world." Pointing to a jar of glycerin from his own Camelina biodiesel experiment, he remarked that he sure would like to find a use for it.

Will growers in Montana, where soybeans are not an option, take to Camelina farming? The 2006 numbers seem to favor Camelina as a rotation crop, Johnson summed up. Crushing Camelina seed yields about 33 percent oil and 67 percent press cake meal; that works out to a seed value of about 9 cents a pound at the crusher; the meal is worth about $230 a ton as cattle feed. "Farmers in eastern Montana tell me that with $4 (a bushel) wheat they get a net return of $52 an acre; at 9 cents a pound for Camelina seed, plus meal sales (for livestock feed), their net return comes out to about $100 an acre. The downside is that there are no subsidies for Camelina."

Initially, though, not revelations about transfats but biofuel issues shed light on a possible Camelina resurgence in the United States. In the 1990s, Montana State University researcher Duane Johnson had been working with a group of growers to establish a canola program with an eye on biodiesel. (Canola is the result of a Canadian plant breeding program that removed most of the erucic acid from rapeseed; in Europe canola is known as “zero-zero rape.”) Johnson just couldn’t get the numbers to work; on the dryland east of the Rockies, canola yields were poor mostly. Johnson diverted the project to biolubricant production because returns on biolubricants are a little better than on biofuel, but that went nowhere when industry threw up political hurdles. Then Johnson read European Union reports investigating a range of oil plants for their suitability in biofuel production. What he found out about Camelina excited him.

Alright, Johnson is an excitable fellow. You wouldn’t describe him as wiry, but he acts wiry; once he’s wormed his way through an enigma he sets out to turn anyone who’ll listen into a believer of a new paradigm. Johnson thinks on his feet: once a skeptical journalist asked to take a photo of him, whereupon Johnson led the man to the pick-up truck of the research station, opened the hood to pull the dipstick from the oil pan – and proceeded to lick the dipstick, with wink and flair no less, proclaiming: “It’s just vegetable oil!” That was one photo surely worth a thousand words.

In research trials Johnson confirmed that Camelina, an undemanding and pest resistant crop cheap to seed, would produce a much better return for the farmer than rapeseed/canola, specifically in marginal growing regions like semi-arid, cold Eastern Montana. "Canola requires $100 to $110 input per acre, including five to six trips across the field, whereas Camelina requires very low input, $45 to $65 per acre. It grows like a weed – you throw the seed on the ground, walk away and don't come back until it's ready to combine," Johnson put it, speaking in 2006.

Camelina is facultative in growth habit, so it can be seeded over a long period. "We've had good results broadcasting the seed as soon as the ground's bare of snow," Johnson said. "When planted into wheat and barley stubble, it controls the volunteers as well as the weeds, it's very allelopathic." Thus Camelina has dryland rotation crop advantages, including the fact that the seed has zero dormancy (no delayed sprouting).

"On Eastern Montana acreage with 10 to 12 inches effective rainfall, Camelina has yielded around 1500 pounds per acre," Johnson said.

With his biofuel focus, Johnson liked to emphasize Camelina use by the ancients as lamp oil. Looking forward, he expected the omega 3 content in Camelina to play a role in its market development. He quoted from medical research pertaining to omega 3 unsaturated fatty acids, that they can reduce inflammation linked to heart disease, stroke, diabetes, arthritis, and other human illness. For these reasons we’re advised to eat ocean fish, he explained. "Phytoplankton in the oceans make omega 3. As the omega 3s move through the food chain they become more concentrated, and cold water fish rely on them for survival in cold climates."

Ah, but there is a global problem, namely species-threatening harvest levels of wild fish stocks, a disastrous course in part blamed on rising omega 3 demand, Johnson said: that’s why the Camelina resurgence has appeal for environmentalists. Not only is cold-pressed Camelina oil a fine food product – think salad oil –, but after biofuel crushing the press cake that still contains good levels of omega 3 can be fed to livestock. A trial was underway to see if feeding Camelina at fish farms would result in omega 3 farmed fish.

Further health benefits of Camelina oil lie in its a cholesterol-reducing effect, according to a Danish study.

Not long, though, and Johnson harked back to his biofuel focus. Which wasn’t hard to do, what with all those semi-trucks blowing by on the highway in front of his office window. Belching sulfur, he emphasized, was one health-damaging aspect of diesel motors: “The sulfur is added as lubricant. Adding 2 percent biodiesel to diesel is one way to replace sulfur as lubricant."

Big industry has big plans for biodiesel, Johnson said. "ADM wants to expand their biodiesel production in the Midwest to 100 million gallons a year." A byproduct when making soybean oil into biodiesel is glycerin. "ADM alone will produce enough glycerin to cover the world." Pointing to a jar of glycerin from his own Camelina biodiesel experiment, he remarked that he sure would like to find a use for it.

Will growers in Montana, where soybeans are not an option, take to Camelina farming? The 2006 numbers seem to favor Camelina as a rotation crop, Johnson summed up. Crushing Camelina seed yields about 33 percent oil and 67 percent press cake meal; that works out to a seed value of about 9 cents a pound at the crusher; the meal is worth about $230 a ton as cattle feed. "Farmers in eastern Montana tell me that with $4 (a bushel) wheat they get a net return of $52 an acre; at 9 cents a pound for Camelina seed, plus meal sales (for livestock feed), their net return comes out to about $100 an acre. The downside is that there are no subsidies for Camelina."

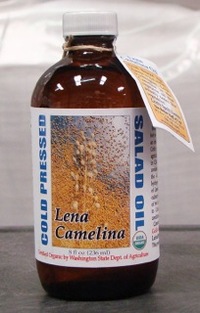

When word of Johnson’s research reached Lentz Spelt Farms, they purchased seed of two Camelina varieties from the farmer co-op who worked with Johnson. One was an Austrian, one a German landrace, both designated for food use in Europe. Thus in 2006 the first Washington State Camelina oil arrived on the shelves of natural foods stores. The label read Lena Camelina.

*****

It was officially a biofuel year, 2006, when the governor signed the Washington State Energy Freedom Program. In November 2006 the state’s first commercial-sized biofuel crusher started up operations at Natural Selection Farms near Sunnyside. The biofuel portion of Lentz Spelt Farms’ Camelina was one of the first crushes. Jon Van Gerpen, head of the biological and agricultural engineering department at the University of Idaho, Moscow traveled to Sunnyside to observe.

"We're interested in what's going on in the region," Van Gerpen said of his journeys to oil seed producers and biofuel start-ups. "This project is curiosity-driven."

After evaluating six different types of oil press machinery, Van Gerpen concluded that medium-size machinery can be operated profitably only if the oil and/or meal goes to niche markets, while small crushers were an altogether losing proposition at that time. "As a matter of fact, a while back we started to talk people out of getting small presses because they're just not cost effective," Van Gerpen related.

His surprise: "People are getting those presses regardless. They seem to like the idea of being energy independent, and they also feel that getting a small press now is a hedge against further (conventional) fuel price increases, they think that eventually there will be savings."

Larry Magill was one of those farmers, planting 80 Camelina acres on his organic farm near Dufur, Oregon. Magill related that he's determined to emulate his grandfather's farming model. No, he's not going to do horse farming per se, but he is adopting the practice of the farm feeding its modern horses, the tractors, combine, trucks. "The old-timers grew around 30 percent of their crops to feed their horses. Today, with new technology, it'll take about 18 percent of my acres to fuel my machinery," Magill said.

The press cake from the Lena Camelina food-grade cold-press went to free-range laying hens at Skagit River Ranch by Sedro-Woolley. The timing couldn’t have been better – the ranch had been selected to participate in a nutritional study by Mother Earth News; the magazine wanted to thrash the big-industry claim that eggs from chicken factories were nutritionally equal to eggs from free-ranging hens. A number of organic operators across the United States were asked to submit eggs to an accredited laboratory.

When Mother Earth News published the analyses, the overall differences were more stark than expected: compared to factory-chicken eggs, free-range eggs averaged one third less cholesterol and a quarter less saturated fat, and were significantly higher in omega 3, vitamin E, and beta-carotene. The lab report on Skagit River Ranch eggs was particularly impressive: omega 3 at 740 milligrams per 100 grams, with the cholesterol at a low 335 milligrams per 100 grams.

Owner George Vojkovich ascribed the outstanding omega 3 content more to the inclusion of Camelina meal in the chicken feed than to grass pasture – chickens, he said, actually don’t eat much grass. “Grass is only about 5 percent of the chicken diet, they’re not like turkeys, turkeys eat about 25 percent grass.”

Vojkovich noted that he blended the Camelina meal into his chicken feed at 25 pounds per ton. “I’m using the Camelina meal on pork, too. It’s the queen of fats. I’ll use all I can get.”

"We're interested in what's going on in the region," Van Gerpen said of his journeys to oil seed producers and biofuel start-ups. "This project is curiosity-driven."

After evaluating six different types of oil press machinery, Van Gerpen concluded that medium-size machinery can be operated profitably only if the oil and/or meal goes to niche markets, while small crushers were an altogether losing proposition at that time. "As a matter of fact, a while back we started to talk people out of getting small presses because they're just not cost effective," Van Gerpen related.

His surprise: "People are getting those presses regardless. They seem to like the idea of being energy independent, and they also feel that getting a small press now is a hedge against further (conventional) fuel price increases, they think that eventually there will be savings."

Larry Magill was one of those farmers, planting 80 Camelina acres on his organic farm near Dufur, Oregon. Magill related that he's determined to emulate his grandfather's farming model. No, he's not going to do horse farming per se, but he is adopting the practice of the farm feeding its modern horses, the tractors, combine, trucks. "The old-timers grew around 30 percent of their crops to feed their horses. Today, with new technology, it'll take about 18 percent of my acres to fuel my machinery," Magill said.

The press cake from the Lena Camelina food-grade cold-press went to free-range laying hens at Skagit River Ranch by Sedro-Woolley. The timing couldn’t have been better – the ranch had been selected to participate in a nutritional study by Mother Earth News; the magazine wanted to thrash the big-industry claim that eggs from chicken factories were nutritionally equal to eggs from free-ranging hens. A number of organic operators across the United States were asked to submit eggs to an accredited laboratory.

When Mother Earth News published the analyses, the overall differences were more stark than expected: compared to factory-chicken eggs, free-range eggs averaged one third less cholesterol and a quarter less saturated fat, and were significantly higher in omega 3, vitamin E, and beta-carotene. The lab report on Skagit River Ranch eggs was particularly impressive: omega 3 at 740 milligrams per 100 grams, with the cholesterol at a low 335 milligrams per 100 grams.

Owner George Vojkovich ascribed the outstanding omega 3 content more to the inclusion of Camelina meal in the chicken feed than to grass pasture – chickens, he said, actually don’t eat much grass. “Grass is only about 5 percent of the chicken diet, they’re not like turkeys, turkeys eat about 25 percent grass.”

Vojkovich noted that he blended the Camelina meal into his chicken feed at 25 pounds per ton. “I’m using the Camelina meal on pork, too. It’s the queen of fats. I’ll use all I can get.”

*****

Back to Blieskastel. The Camelina forums are held at the Orangerie of a former castle on a hill – a more beautiful venue could hardly be imagined. The castle itself was destroyed in one of the wars Europe staged, it seems every ten years they battered each other’s forts and surrounding towns. But the Orangerie escaped major damage and was restored to majestic splendor, tall, tall windows braced by heavy stone walls facing out to the groomed gardens geometrically dissected by walkways. The spacious paths and flower beds invite visions of baroque personages in frilly attire strolling to Händel’s orderly music, flute notes tilting lightheartedly in the slanted sunshine, violin florets.

But it’s farmers and scientists in a mood for discussion who sit at the double rows of tables. They come at the Camelina topic in a four-way approach. Oil seed for biofuel is one focus; in contrast to the biodiesel thrust in the United States, here biodiesel is not well regarded because decentralization favors running engines on straight vegetable oil. At one point, conversion to vegetable-oil-burning motors translated to over 600 small oil crushers in Germany. But, and this is the second prong of the Camelina theme, politics reared an ugly head; a change in vegetable oil taxation squashed the wave of energy independence, an obvious ploy – by both the two largest German parties – to serve corporate business rather than regional enterprise. An estimated 60 percent of small-scale rural oil production disappeared again. Also political is the lobbying power of the rapeseed industry that disadvantages Camelina growers.

The concept of veggie-propelled vehicles is nevertheless gaining steam. John Deere has a big plant in Germany’s Mannheim; engineers there have built a prototype tractor that runs on vegetable oil, the model poised for full-fledged production as soon as the market justifies it. Also in existence is a Fendt rapeseed tractor that runs solely on veggie oil, completely problem-free for over 5000 hours, so far.

Of course, a transition to agricultural traffic by vegetable power is a dauntingly gargantuan projection, never mind converting the stream on the Autobahnen and the inner-city car shuffles to any great extent. In contrast, more immediately reachable are Camelina oil retail opportunities, a topic close to tongue and skin at the forum. A dozen small companies displayed their cold-pressed Camelina oils, and for lunch a grand parade of local chefs dished up an amazing variety of fine cuisine incorporating Camelina oil. It was a smorgasbord the Celts would have appreciated, although many choices on the buffet were potato-based, a vegetable still hiding in the New World in old Celtic times. The chefs excelled in creative multitude of ways to present potato to the palate, Camelina oil harmonizing. If anyone had doubts about the gastronomic dimensions of Camelina, those chefs put them to rest.

At the oil tasting, the range of flavors among the 12 oils of Camelina raised in different microclimates and with different companion crops, surprised the participants who described some of the bouquets as hints of asparagus, pea, kohlrabi, others as “fruity” and “with flowery sub-tones.”

Lunch tasted particularly fine after an in-depth analysis of the health and culinary benefits of Camelina oil. Professor Bertrand Matthäus of the federal research facility for nutrition, Institut für Lipidforschung (investigation of lipids) in Münster, Germany reported on a wide scope of findings. Essential to the human body are two “families” of polyunsaturated fats that cannot be biosynthesized in the body, omega 3 and omega 6 fatty acids, he said. From these fatty acids a number of hormone-like substances are metabolized, the eicosanoides.

Omega 3 has a number of effects, including reduction of cholesterol, the lowering of blood pressure, blood thinning and blood viscosity, as well as inhibition of infections and normalization of heart rhythm, Matthäus said. But omega 3 does not act alone, he stressed: “Omega 3 and omega 6 compete for the same enzyme system.”

Thus the ratio of omega 6 to omega 3 intake becomes the key, which balance has shifted wildly, Matthäus showed with stats from different countries: Greece prior to 1960 had ratios of up to 2 of omega-6-to-omega-3; today’s Japan has a ratio of 4; Britain and northern Europe 15, the USA 16.7, urban India as high as 50. For a baseline Matthäus chose pre-agrarian diets from the early Stone Age, with an omega 6 to omega 3 ratio of 0.8 – in other words, 20 percent less omega 6 than omega 3 was consumed by those ancestors.

Within the raft of edible oils, large differences were analyzed in the ratios between linoleic (omega 6) and linolenic (omega 3) content – peanut oil at 250 : 1; sunflower oil at 126 : 1; olive oil at 9.6 : 1; walnut oil at 4.3 : 1; canola at 2 : 1. Flax oil with 1 : 3.9 and Camelina oil with 1 : 2.3 were the only oils on the list with ratios that favor omega 3.

Matthäus then touched on phytosterols and phytostanols that occur in fatty plant parts.

Camelina shined again in the context of vitamin E content, specifically tocopherols of which there are four: alpha- and beta-tocopherol have strong biological effect, whereas the gamma-tocopherol that’s high in Camelina is strongly efficient as antioxidant, as is delta-tocopherol, Matthäus said. Health-wise pertinent is that vitamin E antioxidants prove beneficial in prevention of cancer and blood circulation problems; they also strengthen the immune system. “Vitamin E catches (oxidizing) radicals in the cells.” In addition, its high gamma-tocopherol content is likely one reason for the long shelf life of Camelina oil.

The erucic acid in Brassica species including Camelina warrants more research, in view of proven beneficent effect but also, at higher levels of consumption, negative impacts. “The upper limit of recommended consumption is around 500 milligrams of erucic acid per day, that comes out to 20 grams of Camelina oil.” That’d be quite the big slug.

But it’s farmers and scientists in a mood for discussion who sit at the double rows of tables. They come at the Camelina topic in a four-way approach. Oil seed for biofuel is one focus; in contrast to the biodiesel thrust in the United States, here biodiesel is not well regarded because decentralization favors running engines on straight vegetable oil. At one point, conversion to vegetable-oil-burning motors translated to over 600 small oil crushers in Germany. But, and this is the second prong of the Camelina theme, politics reared an ugly head; a change in vegetable oil taxation squashed the wave of energy independence, an obvious ploy – by both the two largest German parties – to serve corporate business rather than regional enterprise. An estimated 60 percent of small-scale rural oil production disappeared again. Also political is the lobbying power of the rapeseed industry that disadvantages Camelina growers.

The concept of veggie-propelled vehicles is nevertheless gaining steam. John Deere has a big plant in Germany’s Mannheim; engineers there have built a prototype tractor that runs on vegetable oil, the model poised for full-fledged production as soon as the market justifies it. Also in existence is a Fendt rapeseed tractor that runs solely on veggie oil, completely problem-free for over 5000 hours, so far.

Of course, a transition to agricultural traffic by vegetable power is a dauntingly gargantuan projection, never mind converting the stream on the Autobahnen and the inner-city car shuffles to any great extent. In contrast, more immediately reachable are Camelina oil retail opportunities, a topic close to tongue and skin at the forum. A dozen small companies displayed their cold-pressed Camelina oils, and for lunch a grand parade of local chefs dished up an amazing variety of fine cuisine incorporating Camelina oil. It was a smorgasbord the Celts would have appreciated, although many choices on the buffet were potato-based, a vegetable still hiding in the New World in old Celtic times. The chefs excelled in creative multitude of ways to present potato to the palate, Camelina oil harmonizing. If anyone had doubts about the gastronomic dimensions of Camelina, those chefs put them to rest.

At the oil tasting, the range of flavors among the 12 oils of Camelina raised in different microclimates and with different companion crops, surprised the participants who described some of the bouquets as hints of asparagus, pea, kohlrabi, others as “fruity” and “with flowery sub-tones.”

Lunch tasted particularly fine after an in-depth analysis of the health and culinary benefits of Camelina oil. Professor Bertrand Matthäus of the federal research facility for nutrition, Institut für Lipidforschung (investigation of lipids) in Münster, Germany reported on a wide scope of findings. Essential to the human body are two “families” of polyunsaturated fats that cannot be biosynthesized in the body, omega 3 and omega 6 fatty acids, he said. From these fatty acids a number of hormone-like substances are metabolized, the eicosanoides.

Omega 3 has a number of effects, including reduction of cholesterol, the lowering of blood pressure, blood thinning and blood viscosity, as well as inhibition of infections and normalization of heart rhythm, Matthäus said. But omega 3 does not act alone, he stressed: “Omega 3 and omega 6 compete for the same enzyme system.”

Thus the ratio of omega 6 to omega 3 intake becomes the key, which balance has shifted wildly, Matthäus showed with stats from different countries: Greece prior to 1960 had ratios of up to 2 of omega-6-to-omega-3; today’s Japan has a ratio of 4; Britain and northern Europe 15, the USA 16.7, urban India as high as 50. For a baseline Matthäus chose pre-agrarian diets from the early Stone Age, with an omega 6 to omega 3 ratio of 0.8 – in other words, 20 percent less omega 6 than omega 3 was consumed by those ancestors.

Within the raft of edible oils, large differences were analyzed in the ratios between linoleic (omega 6) and linolenic (omega 3) content – peanut oil at 250 : 1; sunflower oil at 126 : 1; olive oil at 9.6 : 1; walnut oil at 4.3 : 1; canola at 2 : 1. Flax oil with 1 : 3.9 and Camelina oil with 1 : 2.3 were the only oils on the list with ratios that favor omega 3.

Matthäus then touched on phytosterols and phytostanols that occur in fatty plant parts.

Camelina shined again in the context of vitamin E content, specifically tocopherols of which there are four: alpha- and beta-tocopherol have strong biological effect, whereas the gamma-tocopherol that’s high in Camelina is strongly efficient as antioxidant, as is delta-tocopherol, Matthäus said. Health-wise pertinent is that vitamin E antioxidants prove beneficial in prevention of cancer and blood circulation problems; they also strengthen the immune system. “Vitamin E catches (oxidizing) radicals in the cells.” In addition, its high gamma-tocopherol content is likely one reason for the long shelf life of Camelina oil.

The erucic acid in Brassica species including Camelina warrants more research, in view of proven beneficent effect but also, at higher levels of consumption, negative impacts. “The upper limit of recommended consumption is around 500 milligrams of erucic acid per day, that comes out to 20 grams of Camelina oil.” That’d be quite the big slug.

In summing up his lipid research of Camelina, Matthäus said that as with other oils, propitious aspects and a few suspect ones blend together. A best-of-of-all-oils just doesn’t exist, but it is correct to state that in Camelina unfold numerous compounds advantageous to human health and delightful to the palate. So: the oil of the Celts can take its proud place among ancestral foods good for you, with top researchers’ blessings.

Naturopath Ina Kramer of Saarbrücken shared her perspective of Camelina oil as answer to “civilization illnesses.” The low-fat diet trend lately has led us astray, she said, we shouldn’t shy away from healthy fatty acids. “One tablespoon of omega-3-rich oil a day lowers the blood pressure.”

In practice, Camelina oil has a great advantage over supplements such as flax oil, she noted. “It’s hard to get people to take a supplement regularly, it’s easier for them to keep a bottle on the kitchen table and use the oil with their meals.”

Kramer also praised Camelina oil as having cell-renewing traits beneficial in treatment of some skin allergies and eczema. The strong vegetable aroma of Camelina – so persuasive with potato and in salads – needs to be neutralized in skin care products by adding flavors such as lemon juice, she suggested.

At the forum’s display tables stood Camelina salves, cremes, lip balm, soaps, bath oils. Clearly a small Saarland skin care industry oils its gears to lift itself from fledgling status.

Naturopath Ina Kramer of Saarbrücken shared her perspective of Camelina oil as answer to “civilization illnesses.” The low-fat diet trend lately has led us astray, she said, we shouldn’t shy away from healthy fatty acids. “One tablespoon of omega-3-rich oil a day lowers the blood pressure.”

In practice, Camelina oil has a great advantage over supplements such as flax oil, she noted. “It’s hard to get people to take a supplement regularly, it’s easier for them to keep a bottle on the kitchen table and use the oil with their meals.”

Kramer also praised Camelina oil as having cell-renewing traits beneficial in treatment of some skin allergies and eczema. The strong vegetable aroma of Camelina – so persuasive with potato and in salads – needs to be neutralized in skin care products by adding flavors such as lemon juice, she suggested.

At the forum’s display tables stood Camelina salves, cremes, lip balm, soaps, bath oils. Clearly a small Saarland skin care industry oils its gears to lift itself from fledgling status.

*****

Three prongs then – biofuel, politics, biomarket retail. But the forth prong turned out to be the most exciting talk at the forums, namely the resurgence of Mischkultur, the art of intercropping by letting several crops mingle in the field. Enter Thomas Kaiser, engineer-farmer from Bavaria who reminded us of Montana’s Duane Johnson, wiry in his mind, his feet pacing when he’s speaking as though to shed distance between concepts and their verbal expression.

First Kaiser reported from the Institut für Energie und Umwelttechnik (environmental technology), Munich on how to convert diesel engines to run on straight vegetable oils. Then he launched himself into the Mischkultur theme with an early-summer image of his organic barley, haloed as it was by a veritable layer of yellow. You didn’t have to be a farmer to envision this, it’s a common flowering blight above cereal grain fields across the world – the yellow of wild mustard weed.

There should be a useful plant to reduce and replace that darn mustard weed, Kaiser ruminated – “an oil crop plant that behaved similarly.” He got in touch with a scientist in then-East Germany. Kaiser’s wish list was long: the replacing crop plant should have growing characteristics in rhythm with barley; it shouldn’t be aggressive against the cereal, nor should it shade it; in maturing it should keep pace with barley; and, it should require only modest inputs on organic ground.

Right, you say, what a dreamer. But Kaiser received an unequivocal reply from East Germany – Camelina sativa fits the bill!

His Camelina journey led Kaiser into the realm of “gratis factors,” stuff for free. It sounds like one of those late-night TV commercials where you buy a blender and get a chocolate bunny for free, and if you order today we’ll also send you kitchen knives... The monocropper’s intuition reacts exactly like that, to him it sounds like a snake oil recipe to seed an oil crop into barley and not reduce your barley yield by doing so.

On the other hand, the folks who already strove for organic principles and a resurgence of ancestral crops, for them the message of Mischkultur, initially, was like hearing a tune they couldn’t place but had heard before, somewhere, somewhere.

Kaiser pointed out that Mischkultur was practiced until relatively recent eras. “Raising mixed crops had considerable significance until the mid-1700s.” He cited the Saxon king’s secret minister and director of the agronomic institute at the Leipzig university, Professor Doctor Adolph Blomeyer, writing in 1889: “Mixed-seedings can have advantages over single-crop seedings..., a more complete, more varied use of soil can be achieved, (so) harvest yields become richer, larger.”

Blomeyer had been right; Kaiser cited a comparison study from 1999 to 2003 at Pfaffenhofen, Bavaria. Monocrops of spring wheat were compared to Mischkultur spring wheat-Camelina crops. Three of the five years the Mischkultur wheat yielded less than the monocropped wheat; however, the largest wheat yield decline was 1.8 tons per hectare, whereas the largest yield gain when Mischkultur wheat led was a whopping 8.2 tons per hectare. Camelina yields in the Mischkultur ranged from 29.3 tons/hectare to 51 tons/hectare, so even in the years when monocropped wheat yields were slightly reduced there was overall gain.

In a Bliesgau case of double-cropping peas and Camelina, pea yield increased by 35 percent.

In a Bavarian barley-Camelina Mischkultur the malting qualities of the barley were analyzed as superior to those of monocropped barley.

Several Mischkultur growers highlighted the structural gratis factor of Camelina, in that it reduced lodging (the flattening) of cereal stands. They pronounced Camelina as particularly well-matched with Einkorn, Emmer, Spelt.

And so Einkorn found its old friend Camelina again.

By 2009, Mischkultur had risen to such esteem that almost all Camelina production in Austria, Germany and France was raised as mixed crop. At the forum only the Luxembourg growers spoke of disappointing results; eastern European Camelina farmers had not yet experimented with Mischkultur. But otherwise the new paradigm was buoyed by a torrent of optimism – a new day of farming seemed to have arrived as folks related their experiences with double- and triple-crops of all kinds of combinations. Oats and Camelina, oats and Camelina and white clover, oats and condiment mustard and buckwheat, Spelt-Camelina-peas, Einkorn-lentil-Camelina, even carrot and poppy.

Austrian agricultural consultant Birgit Birnstingl spoke about experiments to add trees to Mischkultur systems.

Alas, if in the sunny Orangerie the buzz was on, very little of it resounded among Germany’s mainstream farmers. Meanwhile, globally the biofuel development had run into the problematic situation of pitting fuel acres against food acres. Wasn’t it timely that a Mischkultur resurgence demonstrated a means to raise fuel crops without decline in food production?

There should be a useful plant to reduce and replace that darn mustard weed, Kaiser ruminated – “an oil crop plant that behaved similarly.” He got in touch with a scientist in then-East Germany. Kaiser’s wish list was long: the replacing crop plant should have growing characteristics in rhythm with barley; it shouldn’t be aggressive against the cereal, nor should it shade it; in maturing it should keep pace with barley; and, it should require only modest inputs on organic ground.

Right, you say, what a dreamer. But Kaiser received an unequivocal reply from East Germany – Camelina sativa fits the bill!

His Camelina journey led Kaiser into the realm of “gratis factors,” stuff for free. It sounds like one of those late-night TV commercials where you buy a blender and get a chocolate bunny for free, and if you order today we’ll also send you kitchen knives... The monocropper’s intuition reacts exactly like that, to him it sounds like a snake oil recipe to seed an oil crop into barley and not reduce your barley yield by doing so.

On the other hand, the folks who already strove for organic principles and a resurgence of ancestral crops, for them the message of Mischkultur, initially, was like hearing a tune they couldn’t place but had heard before, somewhere, somewhere.

Kaiser pointed out that Mischkultur was practiced until relatively recent eras. “Raising mixed crops had considerable significance until the mid-1700s.” He cited the Saxon king’s secret minister and director of the agronomic institute at the Leipzig university, Professor Doctor Adolph Blomeyer, writing in 1889: “Mixed-seedings can have advantages over single-crop seedings..., a more complete, more varied use of soil can be achieved, (so) harvest yields become richer, larger.”

Blomeyer had been right; Kaiser cited a comparison study from 1999 to 2003 at Pfaffenhofen, Bavaria. Monocrops of spring wheat were compared to Mischkultur spring wheat-Camelina crops. Three of the five years the Mischkultur wheat yielded less than the monocropped wheat; however, the largest wheat yield decline was 1.8 tons per hectare, whereas the largest yield gain when Mischkultur wheat led was a whopping 8.2 tons per hectare. Camelina yields in the Mischkultur ranged from 29.3 tons/hectare to 51 tons/hectare, so even in the years when monocropped wheat yields were slightly reduced there was overall gain.

In a Bliesgau case of double-cropping peas and Camelina, pea yield increased by 35 percent.

In a Bavarian barley-Camelina Mischkultur the malting qualities of the barley were analyzed as superior to those of monocropped barley.

Several Mischkultur growers highlighted the structural gratis factor of Camelina, in that it reduced lodging (the flattening) of cereal stands. They pronounced Camelina as particularly well-matched with Einkorn, Emmer, Spelt.

And so Einkorn found its old friend Camelina again.

By 2009, Mischkultur had risen to such esteem that almost all Camelina production in Austria, Germany and France was raised as mixed crop. At the forum only the Luxembourg growers spoke of disappointing results; eastern European Camelina farmers had not yet experimented with Mischkultur. But otherwise the new paradigm was buoyed by a torrent of optimism – a new day of farming seemed to have arrived as folks related their experiences with double- and triple-crops of all kinds of combinations. Oats and Camelina, oats and Camelina and white clover, oats and condiment mustard and buckwheat, Spelt-Camelina-peas, Einkorn-lentil-Camelina, even carrot and poppy.

Austrian agricultural consultant Birgit Birnstingl spoke about experiments to add trees to Mischkultur systems.

Alas, if in the sunny Orangerie the buzz was on, very little of it resounded among Germany’s mainstream farmers. Meanwhile, globally the biofuel development had run into the problematic situation of pitting fuel acres against food acres. Wasn’t it timely that a Mischkultur resurgence demonstrated a means to raise fuel crops without decline in food production?

*****

In America, Lentz Spelt Farms had contracted several fields of Mischkultur, Emmer-Camelina double crops and barley-vetch-Camelina triples, on irrigated ground. The post-harvest separation of the crops was time consuming, as was expected. It was apparent that the larger the differences in seed size of the three crops, the more efficient the separation process by screen mill.

Right before harvest a field day. A number of visitors were impressed with the Mischkultur results, especially folks from outside of agriculture, bakers and chefs. As for attending organic farmers, they were interested but skeptical. The effect on conventional farming was nil, just as in Germany.

Although, a tentative approach similar to Mischkultur was a project of Stephen Machado, associate professor of Oregon State University at the Columbia Basin Agricultural Research Center by Pendleton. Machado’s study was driven by the problems of no-till cropping wheat-on-wheat on dryland receiving as little as 11 inches annual precipitation. "The closures of the green pea processors in Eastern Oregon have caused growers to go back to monocropping wheat with no rotational crop in-between," he remarked.

Machado explained that as wheat stubble and straw break down, the carbon-nitrogen ratio is so high that much of the nitrogen is unavailable to the wheat. “Wheat can become auto-toxic (toxic to itself) in monoculture systems.”

Seeding peas into the wheat helps this situation. However, the near-drought conditions when the wheat matures dictate that the peas cannot be allowed to ripen, Machado elaborated. "We used a variety out of the USDA legume breeding program at Pullman. That variety died by itself in late spring... Other pea varieties we used are much more aggressive, so one thing we're looking at is the best time to kill them in the field (with broadleaf herbicide), in March, April, or May. The idea is to get the wheat to benefit maximally from the nitrogen fixed by the peas before competition for water can reduce wheat yield."

Machado’s intercropped wheat plots demonstrated wheat yield increases averaging 12.5 percent.

There may also be microbial benefits, he hypothesized. "Soil microbes are like us, they like to choose their food. The peas introduce different microbes to the soil than the wheat does. These microbes may be beneficial to wheat, or not beneficial. We think they are beneficial, we think that microbes attracted to peas suppress wheat pests."

In an aside, Machado spoke of traditional Mischkultur still practiced today by subsistence farmers in his native Zimbabwe. "It's common practice over there to grow maize together with a legume and pumpkins or watermelons, in the same field. The beans and peas grow up around the corn stalks; after the corn is harvested, by hand, and the pumpkins have been collected, the field is good feed for the livestock."

Machado foresees that the national push to biofuels will change the economics of rotational crops in the Pacific Northwest. As for intercropping so that more than one crop gets harvested, he’s open-minded. "They're doing that up in Canada where they get summer rain, they raise wheat and clover; after they harvest the wheat the clover takes off, and they get a second harvest."

Monocropping Camelina, meanwhile, got a boost when the U.S. Air Force began experimenting with Camelina fuel in its jets; the Camelina Association of Canada announced projections of 1-plus million acres. Before you knew it, Big Oil had its dirty fingers in the Camelina pie.

Right before harvest a field day. A number of visitors were impressed with the Mischkultur results, especially folks from outside of agriculture, bakers and chefs. As for attending organic farmers, they were interested but skeptical. The effect on conventional farming was nil, just as in Germany.

Although, a tentative approach similar to Mischkultur was a project of Stephen Machado, associate professor of Oregon State University at the Columbia Basin Agricultural Research Center by Pendleton. Machado’s study was driven by the problems of no-till cropping wheat-on-wheat on dryland receiving as little as 11 inches annual precipitation. "The closures of the green pea processors in Eastern Oregon have caused growers to go back to monocropping wheat with no rotational crop in-between," he remarked.

Machado explained that as wheat stubble and straw break down, the carbon-nitrogen ratio is so high that much of the nitrogen is unavailable to the wheat. “Wheat can become auto-toxic (toxic to itself) in monoculture systems.”

Seeding peas into the wheat helps this situation. However, the near-drought conditions when the wheat matures dictate that the peas cannot be allowed to ripen, Machado elaborated. "We used a variety out of the USDA legume breeding program at Pullman. That variety died by itself in late spring... Other pea varieties we used are much more aggressive, so one thing we're looking at is the best time to kill them in the field (with broadleaf herbicide), in March, April, or May. The idea is to get the wheat to benefit maximally from the nitrogen fixed by the peas before competition for water can reduce wheat yield."

Machado’s intercropped wheat plots demonstrated wheat yield increases averaging 12.5 percent.

There may also be microbial benefits, he hypothesized. "Soil microbes are like us, they like to choose their food. The peas introduce different microbes to the soil than the wheat does. These microbes may be beneficial to wheat, or not beneficial. We think they are beneficial, we think that microbes attracted to peas suppress wheat pests."

In an aside, Machado spoke of traditional Mischkultur still practiced today by subsistence farmers in his native Zimbabwe. "It's common practice over there to grow maize together with a legume and pumpkins or watermelons, in the same field. The beans and peas grow up around the corn stalks; after the corn is harvested, by hand, and the pumpkins have been collected, the field is good feed for the livestock."

Machado foresees that the national push to biofuels will change the economics of rotational crops in the Pacific Northwest. As for intercropping so that more than one crop gets harvested, he’s open-minded. "They're doing that up in Canada where they get summer rain, they raise wheat and clover; after they harvest the wheat the clover takes off, and they get a second harvest."

Monocropping Camelina, meanwhile, got a boost when the U.S. Air Force began experimenting with Camelina fuel in its jets; the Camelina Association of Canada announced projections of 1-plus million acres. Before you knew it, Big Oil had its dirty fingers in the Camelina pie.

*****

At Blieskastel, the Camelina Mischkultur Forum this year featured in broad strokes where we stand in the big picture of industrialization. Albert Schweitzer was mentioned, how his musings on ethics might apply to eco-farming today. Nelson Rockefeller was discussed, how his 1946 scheme of Green Revolution was pretext to the coupling of agriculture with Big Oil, in effect constructing a global agribusiness as an extension of the Big Oil monopoly. And today, also thanks in part to the Rockefeller foundation, we’ve arrived at a dictatorship over crop plant genes entirely alien to nature – genetically modified organisms (GMOs).

Industry in general is diametrically opposed to life; industrial farming sucks up fossil and nuclear energies, centralizes operations, rules the economies of industrialized nations, herds us into globalization, and slowly but surely extinguishes farmer enterprise. Finally, Gigantismus. A translation isn’t needed here – Gigantismus is precisely the point where the last vestiges of the humane drown in seas of polluted weather.

Industry in general is diametrically opposed to life; industrial farming sucks up fossil and nuclear energies, centralizes operations, rules the economies of industrialized nations, herds us into globalization, and slowly but surely extinguishes farmer enterprise. Finally, Gigantismus. A translation isn’t needed here – Gigantismus is precisely the point where the last vestiges of the humane drown in seas of polluted weather.

Thus spoke Professor emeritus Ernst Schrimpff who teaches at the Hochschule Weihenstephan, Bavaria. He’s a member of a federal association for vegetable oil production, and he also belongs to an association for political ecology that honors Ernst Friedrich Schumacher, the German-born British economist who’d attained world fame with his 1973 bestseller Small is Beautiful.

Schrimpff not only decried the use of agrochemicals, but challenged growers to strive beyond organic, beyond Mischkultur. It’s high time for a paradigm shift, and a new label, he said: Naturnahe. “Nature-Near.”

Before we let Schrimpff continue, a look at the German system of organic certifications in all their divergences. Unlike the American USDA Organic emblem that clearly and simply differentiates an item – it’s organic or it’s not –, German organic rules are established and supposedly overseen by various associations. Demeter is said to be the highest level of organic practice; next comes the Bioland label; then Naturland; then Gäa (predominant in East Germany); lastly, there is a loosely applied European symbol for Öko (“eco”-logical). And so organic shoppers in Germany negotiate a maze of organic labeling, hopefully without falling prey to all kinds of other labels with some sort of “natural” proclamation. Additionally, in most stores the organic products do not claim separate space in the aisles but appear haphazardly amid conventional stuffs.

Naturnahe. “Nature-Near,” Schrimpff said, further reduces the energy demands of food, feed, fiber, and agricultural oil production. Conventional agriculture consumes 5.14 megawatt hours per year per hectare, organic farming 1.58, the Naturnahe approach 0.72. Expressed in percentages, organic farms use but 31 percent, Naturnahe farms a mere 14 percent of the energy that conventional farms and agribusiness must invest.

The crux of Nature-Near farming is Nullbodenbearbeitung, Schrimpff emphasized. In English that term is a bit shorter – “no-till.” It’s also called “direct-seed.” Across much of the world no-till is inseparably linked to the military-industrial complex – think defoliation in Vietnam –, because no-till relies heavily on Round-Up or similar very-broad-spectrum herbicide. In fact, the global push to no-till has been one huge boom in agrochemical sales. (At issue is the “green bridge effect” whereby volunteer plants are host to plant diseases that subsequently intensify their spread in the following monocrop; to disrupt this green bridge, and also to curb weeds, no-till producers see heavy-dose herbicides as their only option. The organic method to prevent soil erosion is to use an “undercutter,” an implement that cuts plant roots a very short distance beneath the soil surface, without turning the soil over: “conservation tillage” is the term.)

Injecting no-till principles into organic Mischkultur certainly ranks a novel idea, but Schrimpff said it can be done. He spoke of farms in Brazil where organic no-till has been practiced for years, and he showed pictures of direct-seeding on German fields.

No-till, in any system, is the answer to erosion problems that have plagued agriculture almost since its very beginnings. That’s what put Schrimpff on his thinking curve, for many years, he said, he studied erosion issues. Equally pertinent is carbon sequestration – Schrimpff noted that undisturbed soil is able to store four times as much carbon as trees do.

The soil, the ground, the dirt. It’s seen as “the last frontier of science” by some agronomists; for Schrimpff it’s synergy. Just look how those earthworms fashion “straw stars” and pull some straw underground. Could a farmer have a better workforce? “Conventional practices (in Germany) result in 15 earthworms per square meter; after 20 years of organic practices, over 300 work that space, and the natural potential approaches 600 earthworms per square meter.”

At 300 worms/square meter, up to four tons of surface crop residue per hectare are turned into worm-humus. Those four tons represent 140 kilograms of nitrogen per hectare (almost 120 pounds N/acre).

Earthworm tunneling creates underground tubes that in German soils reach depths of about 1.2 meters, Schrimpff said. One earthworm-tube effect is considerable oxygen release into the air while carbon stays behind in the soil.

Again extrapolating from those 300 worms per square meter, 720 meters of worm-tunneled tubes wind through every square meter 1.2 meters deep – in volume that’s 21 liters. This means that worm-happy ground can absorb 75 liters of water per hour.

In German growing conditions, Schrimpff said, “earthworms are active from September to July; the other two months they are in summer-sleep.”

The earthworms are joined by hordes of other subterranean critters, worms of other stripes, and arachnids, centipedes, beetles, and multitudes of insect larvae: 10,880 specimens of this fauna in the first 12-inch layer of one square meter of healthy organic soil; expressed in grams, 51.7 per square meter of writhing, chomping, burrowing creatures, just imagine the activity, Schrimpff said.

And those are only the organisms visible to the eye. Microscopic soil inhabitants count by the millions, billions, 1,000,000,000,000 bacteria alone in that 12-inch depth of a square meter organically farmed, 11,000,000,000 fungi, 500,000,000,000 single-cell organisms.

Park the plow, Schrimpff exhorts. Let your tiller rest. “When seeding, the ground gets lightly scratched, that’s all.”

Organic no-till boosts the root development of crop plants, he said; plant diseases decline as the whole system achieves a higher self-sustaining level. Naturnahe gives the maxim “back-to-the-roots” a whole new meaning.

Before his audience got totally lost in the dark cosmos of a billion soil microbes, Schrimpff pulled us back to the surface with photos of trees. Agroforestry, he noted, also belongs to the Nature-Near concept.

Plant diversity is paramount here, too, he said, commenting on a picture of wheat-poplar monocultures in France.

A tree-mix of several deciduous species queuing between wheat strips, also in France, “is already much better.”

Next an image from England, organic cropping interspersed with single rows of several types of fruit trees, a three-dimensional greening.

Lastly, nuts and fruits, and trees raised for timber in strips dissecting grain production – agroforestry at its best!, Schrimpff proclaimed: “Besides Camelina oil and its press cake, and cereal grain, fruits and timber! Such Agroforestry Camelina Mischkulturen lessen the climate problem. Soils degraded by chemicals can recover their fertility and productivity through Nature-Near farming. Farmlands that have become gigantic and treeless bare can be returned to a scape smaller-sized and therefore more nature- and human-friendly. Naturnahe farming furthers biodiversity!”

Schrimpff’s passionate summing up evoked an echo of the permaculture movement that two Australians had started in the 1970s; they, in turn, had based much of their theory on a 1929 book on “Permanent Agriculture.” It’s as though the concept mutates a little and reappears every 40 years...

Permaculture embraced a wider ring of concepts, and appealed primarily to the back-to-the-land movement in the post-1960s era of anti-establishment agitation. In contrast, Schrimpff hopes to reach the broad base of Europe’s agriculturists with his Naturnahe ideal.

What did the attending organic farmers think? Agreeing with Schrimpff in principle, in practice they still periodically resort to the undercutter like their American counterparts do. As for swaying conventional growers to consider Naturnahe concepts, not much chance of that, commented one organic Spelt Mischkultur farmer who said that his practices have worked well in financial terms: “The neighbors see that I’m able to buy new machinery and equipment more often than they, and they see that I can take a vacation more often than they can, but they’re not changing their conventional farming practice.”

Schrimpff not only decried the use of agrochemicals, but challenged growers to strive beyond organic, beyond Mischkultur. It’s high time for a paradigm shift, and a new label, he said: Naturnahe. “Nature-Near.”

Before we let Schrimpff continue, a look at the German system of organic certifications in all their divergences. Unlike the American USDA Organic emblem that clearly and simply differentiates an item – it’s organic or it’s not –, German organic rules are established and supposedly overseen by various associations. Demeter is said to be the highest level of organic practice; next comes the Bioland label; then Naturland; then Gäa (predominant in East Germany); lastly, there is a loosely applied European symbol for Öko (“eco”-logical). And so organic shoppers in Germany negotiate a maze of organic labeling, hopefully without falling prey to all kinds of other labels with some sort of “natural” proclamation. Additionally, in most stores the organic products do not claim separate space in the aisles but appear haphazardly amid conventional stuffs.

Naturnahe. “Nature-Near,” Schrimpff said, further reduces the energy demands of food, feed, fiber, and agricultural oil production. Conventional agriculture consumes 5.14 megawatt hours per year per hectare, organic farming 1.58, the Naturnahe approach 0.72. Expressed in percentages, organic farms use but 31 percent, Naturnahe farms a mere 14 percent of the energy that conventional farms and agribusiness must invest.

The crux of Nature-Near farming is Nullbodenbearbeitung, Schrimpff emphasized. In English that term is a bit shorter – “no-till.” It’s also called “direct-seed.” Across much of the world no-till is inseparably linked to the military-industrial complex – think defoliation in Vietnam –, because no-till relies heavily on Round-Up or similar very-broad-spectrum herbicide. In fact, the global push to no-till has been one huge boom in agrochemical sales. (At issue is the “green bridge effect” whereby volunteer plants are host to plant diseases that subsequently intensify their spread in the following monocrop; to disrupt this green bridge, and also to curb weeds, no-till producers see heavy-dose herbicides as their only option. The organic method to prevent soil erosion is to use an “undercutter,” an implement that cuts plant roots a very short distance beneath the soil surface, without turning the soil over: “conservation tillage” is the term.)

Injecting no-till principles into organic Mischkultur certainly ranks a novel idea, but Schrimpff said it can be done. He spoke of farms in Brazil where organic no-till has been practiced for years, and he showed pictures of direct-seeding on German fields.

No-till, in any system, is the answer to erosion problems that have plagued agriculture almost since its very beginnings. That’s what put Schrimpff on his thinking curve, for many years, he said, he studied erosion issues. Equally pertinent is carbon sequestration – Schrimpff noted that undisturbed soil is able to store four times as much carbon as trees do.

The soil, the ground, the dirt. It’s seen as “the last frontier of science” by some agronomists; for Schrimpff it’s synergy. Just look how those earthworms fashion “straw stars” and pull some straw underground. Could a farmer have a better workforce? “Conventional practices (in Germany) result in 15 earthworms per square meter; after 20 years of organic practices, over 300 work that space, and the natural potential approaches 600 earthworms per square meter.”

At 300 worms/square meter, up to four tons of surface crop residue per hectare are turned into worm-humus. Those four tons represent 140 kilograms of nitrogen per hectare (almost 120 pounds N/acre).

Earthworm tunneling creates underground tubes that in German soils reach depths of about 1.2 meters, Schrimpff said. One earthworm-tube effect is considerable oxygen release into the air while carbon stays behind in the soil.

Again extrapolating from those 300 worms per square meter, 720 meters of worm-tunneled tubes wind through every square meter 1.2 meters deep – in volume that’s 21 liters. This means that worm-happy ground can absorb 75 liters of water per hour.

In German growing conditions, Schrimpff said, “earthworms are active from September to July; the other two months they are in summer-sleep.”

The earthworms are joined by hordes of other subterranean critters, worms of other stripes, and arachnids, centipedes, beetles, and multitudes of insect larvae: 10,880 specimens of this fauna in the first 12-inch layer of one square meter of healthy organic soil; expressed in grams, 51.7 per square meter of writhing, chomping, burrowing creatures, just imagine the activity, Schrimpff said.

And those are only the organisms visible to the eye. Microscopic soil inhabitants count by the millions, billions, 1,000,000,000,000 bacteria alone in that 12-inch depth of a square meter organically farmed, 11,000,000,000 fungi, 500,000,000,000 single-cell organisms.

Park the plow, Schrimpff exhorts. Let your tiller rest. “When seeding, the ground gets lightly scratched, that’s all.”

Organic no-till boosts the root development of crop plants, he said; plant diseases decline as the whole system achieves a higher self-sustaining level. Naturnahe gives the maxim “back-to-the-roots” a whole new meaning.